Nikon Introduces ASTM E2737 Detector Evaluation Package

Nikon Metrology's Detector Evaluation Package in accordance with ASTM E2737 offers automated analysis of image data with performance trend analysis.

Share

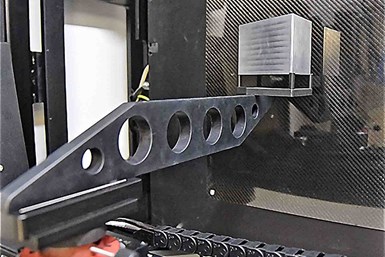

A light metal version of the Nikon Metrology ASTM E2737 Detector Evaluation Package in use within one of its X-ray CT systems. Here, the phantom has been relocated from its usual position on the manipulator so that it is adjacent to the digital detector, where it performs image burn-in.

Photo Credit: Nikon Metrology

Nikon Metrology's Detector Evaluation Package offers automated analysis of image data with performance trend analysis. To help users of Nikon Metrology's X-ray CT systems to process-check their detector performance throughout service, the company has launched a monitoring kit in accordance with the globally accepted standard, ASTM E2737.

The ASTM E2737 Detector Evaluation Package is available to suit the range of Nikon Metrology’s X-ray CT inspection, metrology and large-envelope CT systems. All of the manufacturer’s X-ray sources are supported, including rotating target technology and the 450kV microfocus source, in addition to the full range of detectors.

The package comes with pre-calibrated artefact five-groove wedge phantom and customized bracketry with quick-change adapters that allow the operator to secure the phantom in the right positions. Dedicated software performs all necessary functions, including artefact manipulation, image collection and data analysis, and then generates a detailed report. The streamlined workflow is meant to relieve the operator of manual intervention and simplify the procedure such that it can be carried out by an operator who knows little about ASTM E2737 or X-ray CT.

Data is obtained on nine detector parameters: spatial resolution, contrast sensitivity, material thickness range, signal-to-noise ratio, signal level, image burn-in, image lag, offset value and bad pixel distribution.

The long-term performance and stability of the detector can be tracked throughout its service life. Consistency can be compared with a user-defined baseline and customizable thresholds and warnings. Results from all nine ASTM E2737 tests are stored every time a suite of measurements is made so they can be interrogated at any time. Graphical and tabular presentation of the results aids visualization.

Related Content

-

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

-

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)