A Production Welding System Run by Cobots

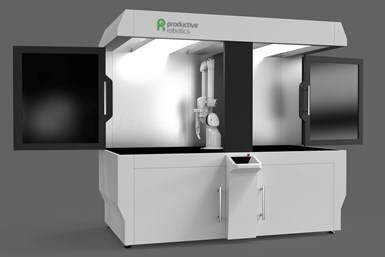

Productive Robotics unveils the industry's first production welding system run by cobots.

Share

Productive Robotics introduces its augmented intelligent, vision-enabled, teach-by-touch 7-axis cobot production welding system, the OB7 cobot.

Conventional robot-run welding systems use a lazy susan mechanism to rotate parts into the welding zone while an operator sets up another part. Productive Robotics eliminates the lazy susan from its design. The company designed a 4 × 8 ft table separated into two halves and fully enclosed. The operator sets up one part, shuts the door and moves to the other side to set up the second part while the cobot welds the first one. The company says simultaneous part setup and welding supports high volume production without interruption.

Productive Robotics also says 7-axis OB7 collaborative cobots can automate repetitive tasks, reduce setup time and perform a variety of machine operations. The cobots are designed to be able to perform machine, lathe, mill and EDM machine tending and deburring. Productive Robotics also says the cobots are capable of gluing, bonding and part making. A proprietary user interface that needs no programming enables operators to teach OB7 by simply showing it each step of a job.

OB7 possesses sight through OB Vision, a development from Productive Robotics introduced earlier this year. The sighted cobots reduce the need for fixtures and staging parts for pickup, two bottlenecks when it comes implementing collaborative robots. Fabricators can deploy the cobots faster and produce more complex parts while minimizing costs.

Each of the OB7’s joints can rotate 360 degrees in both directions. The cobot can sense collisions at every joint, triggering a safe stop when an event occurs. The OB7 can also be stopped with an operator’s hand and restarted with a tap on one of its joints. When running at collaborative speeds, guarding is not required, the company says. For high speed operations, a laser safety scanner is available.

To automate OB7, fabricators can add a Productive Robotics parallel electric gripper or end effector, patented robot rolling stand and work table. The cobot is also compatible with other grippers, cameras and accessories. Data collection is supported by Productive Robotics’ cloud analytics system making it easy for small to medium-sized job shops to implement real-time reporting on cobot activity. Installation of the OB7 takes approximately two hours.

Related Content

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.