New Milling Series From Kyocera Provides Deeper Depth of Cut

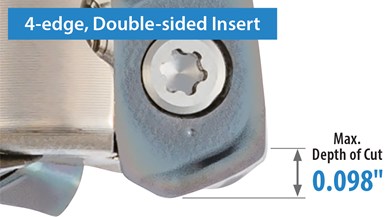

The MFH-Max reduces the number of passes needed to machine the workpiece with its ability to take on deeper depths of cut (max. 0.098" / 2.5 mm).

Share

Kyocera Precision Tools has expanded their indexable high-feed milling line.

According to the company, the MFH-Max provides excellent chip removal performance in various applications, including automotive parts, difficult-to-cut materials and mold machining. With the ability to take on deeper depths of cut (max. 0.098" / 2.5 mm), the MFH-Max reduces the number of passes needed to machine the workpiece. The MFH-Max also supports various milling operations including shouldering, slotting, helical milling and ramping applications.

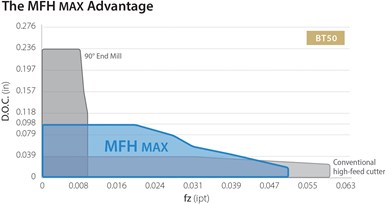

Kyocera says its introduction of the MFH-Max provides a new alternative to conventional 90° end mills when roughing to medium-finishing. The MFH-Max reportedly provides more capabilities than conventional high-feed mills by reducing the number of tool paths and machining time when cutting workpieces with large variations in machining margins.

The MFH-Max uses economical, four-edge, double-sided inserts with a unique convex cutting edge design. These inserts are available in PR15-series PVD insert grades with Kyocera’s proprietary Megacoat Nano coating technology and a wear resistant CVD grade to cover a wide range of materials from steel, stainless, cast iron and difficult-to-cut-materials.

Kyocera says other benefits of the MFH-Max include a large max depth of cut, high chip removal ratio, long tool life, stable machining with an anti-vibration design and a convex insert cutting edge that reduces impact when entering the workpiece.

Related Content

-

Big Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

-

Ceratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.