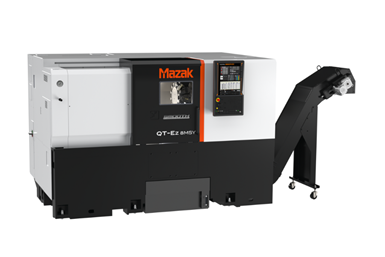

Mazak Horizontal Turning Center Enables Versatile Machining

The QT-Ez 8MSY horizontal turning machine integrates seamlessly with bar feeders and robots, and accepts many additional options to tailor it to the needs of any shop.

Share

Mazak’s QT-Ez 8MSY horizontal turning machine features milling and Y-axis capabilities paired with a second turning spindle. The versatile, automation-ready machine also integrates seamlessly with bar feeders and robots, and accepts many additional options to tailor it to the needs of any shop.

The QT-Ez 8MSY features a 20" bed sports an 8" chuck as standard equipment, with a 6" chuck as optional. Available machine turrets include two-axis drum style with a bolt-on or BMT55 turret for rotary tool applications.

The QT-Ez 8MSY uses an A2-6 spindle mount with 5,000 rpm, 20 hp (14.9 kW), 123 ft-lbs (17 Nm) of torque and a 2" (50.8 mm) bar capacity. It handles parts up to 23.47" (596 mm) long. The turret milling spindle offers 6,000 rpm with 7.5 hp (5.59 kW) and 25.8 ft-lbs (3.57 Nm) of torque. A 6,000 rpm second turning spindle with a 5" chuck accepts an optional through-hole package for shaft transfer applications.

For further productivity, the QT-Ez 8MSY accepts a range of automation solutions from simple bar feeders and parts catchers to full cooperative robot installations, such as Mazak Automation Systems’ cobot cell system models, the CC-10 and CC-16.

Related Content

-

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

-

Okuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

-

Second B-Axis Improves Efficiency of Swiss-Type Machining

A highly stable, fully programmable B-axis on the subspindle of Nomura DS’s 20J3XBTC enables users to more quickly machine complex parts complete.