Kyocera SGS End Mills Feature Seven-Flute Design

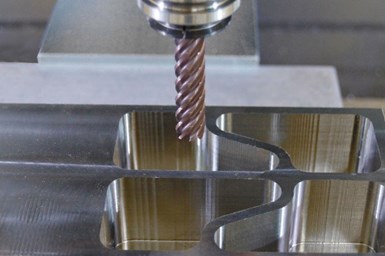

The H-Carb Series 77 end mills feature a specialized core and flute design to improve rigidity and chip flow while reducing deflection.

Share

Kyocera SGS Precision Tools has expanded its H-Carb seven-flute, high-efficiency end mill series with an array of larger corner radii options.

The H-Carb Series 77 end mills specialize in deep axial trochoidal and high-speed machining applications and are offered in various lengths of cut. The specialized core and flute design improve rigidity and chip flow while reducing deflection. The seven-flute design is designed to enable superior finishes at higher speed and feed rates versus five- and six-flute tools.

The H-Carb portfolio now includes 72 new tools featuring 2-, 3- and 4-mm corner radius sizes and are available in three lengths of cut (2.5×D, 3×D and 4×D). Coatings are available in Ti-namite-A and Ti-namite-M, making them suitable for dry machining in ferrous-based materials such as cast irons and numerous carbon steels. The chipbreaker profile is standard with a wide range of square end and corner radii options offered to meet a variety of machining specifications.

Benefits of the portfolio include a heavy-duty core and specialized flute design for improved rigidity, chip flow and reduced deflection; a chipbreaker profile that aids in chip flow, especially in deep pocketing operations; deep pocketing and slotting capability using the various lengths of cut offered applying a trochoidal tool path; and CAM programming methods using high-efficiency machining by applying trochoidal tool paths and incorporating constant cutter engagement.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)