Hypertherm Associates Software Programs Multiple Robots

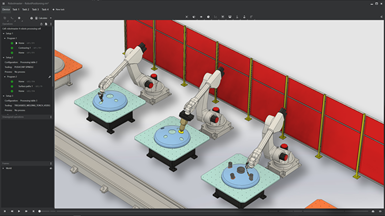

Robotmaster 2024 is designed to program multiple robots to perform a variety of processes within the same cell environment.

Share

Hypertherm Associates has introduced the latest version of its offline programming software with the launch of Robotmaster 2024.

Addressing key market trends, Robotmaster 2024 supports programming multiple robots in a single work cell and meets the demand for automatic trajectory optimization and robotic error correction. In addition, the software update includes improvements to the cell and tooling editor, as well as improvements to the user experience and user interface to ease the programming experience.

Robotmaster 2024 is designed for users who need to program multiple robots to perform a variety of processes within the same cell environment. The ability to program multiple robots enhances the programming workflow and gives the user a single view of the entire system to review the workspace for collisions.

Robotmaster 2024 also comes equipped with Auto Solve, a new automatic optimization and error correction tool. Auto Solve empowers users of all levels of expertise to program industrial robots confidently in alignment with Hypertherm Associates’ mission to deliver an intuitive and easy-to-use software solution.

“Auto Solve leverages our users’ favorite optimization and correction tools. We’ve designed this new feature so that users can optimize the robot trajectory and correct robotic errors in a single click,” says Daniel Marcovici, Hypertherm Associates senior product owner for Robotmaster robotic software.

Natalie Adams, Hypertherm Associates product marketing manager for Robotmaster robotic software, says, “This latest version of our robotic programming software includes new features and functionality that not only decreases programming time but also removes many of the programming nuisance’s robot programmers encounter.”

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.png;maxWidth=300;quality=90)