HGG Profiling Software Suites Increase Material Usage

The ProCAM and ProCAM Lite software suites are designed to increase throughput in profiling applications.

Share

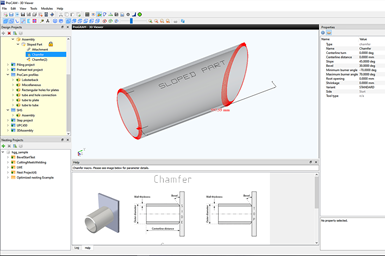

HGG Profiling Equipment Inc.’s ProCAM and ProCAM Lite software suites are designed for HGG profiling machines. Designed in-house, the software synthesizes HGG’s 3D profiling knowledge it into a software system designed to maximize throughput and material usage.

The ProCAM suite features:

- ProCAD provides direct connection to and from several leading CAD/CAM companies including Tekla Structures, SDS/2, AutoCAD, SolidWorks Inventor, Bocad and more.

- ProGRAM gives users the ability to design parts with HGG’s extensive predefined macro shape library.

- ProMIS is a management information system that uses real-time machine data to create reports on cutting performance, processing speeds and productivity.

- Advanced nesting algorithms enable users to maximize material usage and minimize waste.

- Stock Manager enables users to manage stock material and use available material for nesting.

- Stock Manager can be combined with the label printer and scanner option to enable track-and-trace functionality. Operators can simply scan the material loaded on the machine and it automatically loads the correct cutting data.

HGG has partnered with several industry CAD/CAM companies to ensure seamless integration and transfer of data from design through data processing to machine. HGG recently partnered with SDS/2 to create a plugin that directly links to ProCAM. The plugin enables direct definition of cutting information in the SDS/2 CAD model, including detection of holes and pipe notches.

ProCAM Lite is a free software program that gives users the ability to view and check cutting details on various profiles without a cutting machine or intermediary viewing software. Users can review all parameters and weld details for a project before cutting and production, including root openings and markings, for any DSTV, NC, XML or PCD file.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

.jpg;maxWidth=300;quality=90)