HCL Technologies Adds Support For Barrel Tools in Milling Operations

Barrel tool support is beneficial for mold makers and manufacturers of complex parts in industries such as automotive and aerospace.

Share

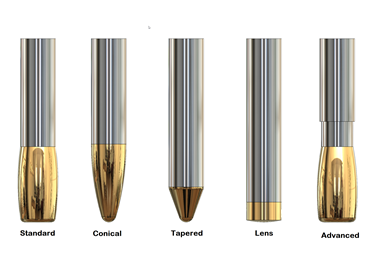

HCL Technologies, a leading global technology company, announces the addition of barrel tool support in HCL CAMWorks Version 2022. CAMWorks now supports standard, conical tangent, tapered, lens and advanced user-defined barrel tools utilized in CNC milling operations.

According to the company, barrel tool support was added in direct response to CAMWorks customer feedback and is beneficial for mold makers and manufacturers of complex parts in industries such as automotive and aerospace. As demand increases for lightweight components with higher surface finishes, barrel tools are leveraged by machine shops to improve productivity and surface finish of machined parts. Barrel tools reduce cycle times for finish and semi-finish milling operations with increased stepdown into the material with each pass, and due to their unique tool geometry, also provide improved surface finish with fewer cutting passes.

With the new Barrel Tool interface in HCL CAMWorks Version 2022, users can now view, edit and save barrel tools in the CAMWorks Technology Database (TechDB). Barrel tools can also be filtered, identified and added to the user-specific tool cribs in CAMWorks. Options for maximum diameter and corner radius of the barrel tools are also included in this new HCL CAMWorks Version 2022. CAMWorks will notify the user if the tool geometry falls outside the defined parameters.

HCL CAMWorks says support for barrel tools expands the technologies available within integrated CAD/CAM to accelerate production and streamline machining.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.