GibbsCAM Software Update Features Digital Connectivity

Version 2024 provides up-to-date cutting tool data and 3D models of cutting tools and toolholders.

Share

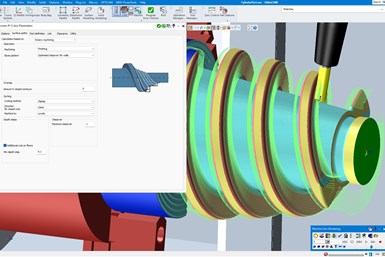

GibbsCAM’s new software release, GibbsCAM 2024, is designed to boost end-user productivity for programming advanced machining centers. The software features a number of enhancements, including digital connectivity.

Version 2024 provides direct integration with Sandvik Coromant’s CoroPlus Tool Library. It provides up-to-date cutting tool data and 3D models of cutting tools and toolholders. All data is verified and adheres to the ISO 13399 international standard for cutting tool data representation and exchange. The cloud-based nature of the tool library means that users of GibbsCAM 2024 can access data from anywhere with an internet connection.

The software introduces new post-processor configuration options for setting standard and custom post defaults, including support for tool center point (TCP) or rotary clamps. Furthermore, a new tool to streamline the setup of the CAM environment now enables editing and restriction of work fixture offsets. GibbsCAM 2024 supports multiple fixture stacking, and now unused fixtures can be retained on the machine for simulation and collision checking purposes.

According to GibbsCAM, working with CAD data is easier. Users can interrogate virtual points for dimensioning part geometry such as edge mid points, end points, intersection, circle centre and circle quadrants directly from the 3D model. A visualization tool can map the curvature and the relevant taper/draft angle directly onto the 3D mode, which is useful for analyzing the minimum tooling diameter required to cut a part since it negates the need to pull extra reference geometry.

GibbsCAM 2024 improves the flexibility of form tools in milling processes. Using the Real profile option which uses the exact cutting tool profile, or the Monotonic profile which will disable any toolpath that uses the tool undercut form. For 3D solid form tools, another option for nominal parameters will only use the major diameter and tip radius for toolpath calculation according to tool manufacturer recommendations, while using the 3D form tool for simulation. Additionally, a new mill cutoff process for mill-turn machines and bar-fed mills now supports perpendicular cutting with an end mill or parallel cutting with a side mill or slitting saw.

Rest machining has been improved when contouring and pocketing strategies are used together with “material only” active now creates a more efficient toolpath with reduced air cuts. Other contour improvements include smoother ramping that generates a continuous contour wherever possible instead of multiple ramping lead in and lead out movements.

New five-axis features include an optimized stepover feature for finishing walls and cylindrical or conical floors that creates a better, more consistent surface finish. New geodesic operations perform straight cuts on end boundaries and improve hole filling to prevent the tool dropping down into open cavities. Other improvements include user-defined tool orientation on lead in and lead out movements, and linked entry feed distance. Multiaxis machining enhancements include better management of 3D containments, improved point distribution, ramp offset for the first pass on roughing cycles, user defined start points for finishing and tool tilting during helix entries.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

.jpg;maxWidth=300;quality=90)