EDM Network Wire EDM Features Four-Axis Cutting

The EDMMax 434W fast-wire EDM includes four-axis cutting capability that enables it to cut 3D support structures or other shop-related parts.

Share

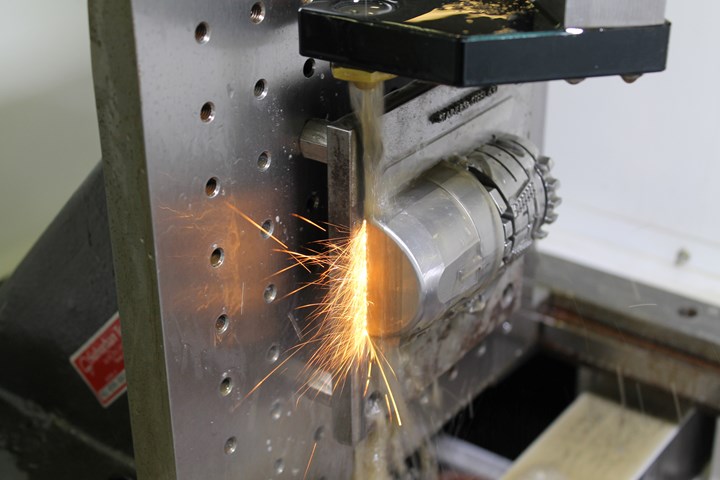

EDM Network Inc.’s EDMMax 434W is designed to be an economical, fast-wire EDM solution for 3D-printed metal removal on parts like the mold inserts above.

Among other applications, the EDMMax 434W enables users to optimally cut 3D-printed mold inserts from their build plates. The fast-wire EDM has a build plate size of 400 × 400 mm and includes four-axis cutting capability that enables it to cut 3D support structures or other shop-related parts; it uses a “reusable” 0.007'' diameter molybdenum high tensile wire.

Other EDMMax 434W features includes an on-board CAD system, and users can import programs via a USB port or LAN system. Three Pass Cutting technology is included for improved surface finishes and part accuracy.

This fast wire EDM solution is available in eight models, including both vertical and horizontal cutting; most models include the four-axis on-board CAD system. All of EDM Network’s fast wire EDMs include on-site setup and training.

Related Content

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

.jpg;maxWidth=970;quality=90)