Magazine Bar Feeder Enables Unattended Operation

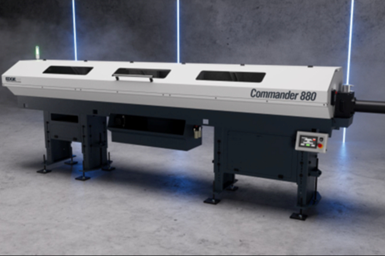

Edge Technologies introduces its Commander 8-80 magazine bar feeder, which enables unattended operation with its large magazine capacity.

Share

Autodesk, Inc.

Featured Content

View MoreThe Commander 8-80 from Edge Technologies is a compact, magazine-style bar feeder that features an 8-80-mm bar diameter capacity range for feeding 12′ and 6′ length round, square, hexagonal and shaped bar stock into fixed headstock CNC lathes. With a large magazine capacity enabling unattended operation, the Commander 8-80 offers the advantage of automatic bar loading with a small footprint.

The loading storage capacity is 406 mm (16.0") deep. Bars are loaded from the front of the bar feeder. Large diameter bars are lowered into the channel area with a “soft-load” device. Material is then guided into the lathe within urethane channels, eliminating the potential for marring of the bars’ surfaces. Bar stock with lengths up to 3,800 mm (12'-6") can be loaded by the Commander 8-80. With the newly designed oil-filled channel sets, changeovers are completed within minutes and allow for quiet operation, according to Edge Technologies. The main beam and support stands are designed to be resistant to flex, enabling vibration from bent bars to be at a minimum. An oversized front steady claims to eliminate harmonics as the material is transferred from the bar feeder to the lathe.

The Commander 8-80 is a magazine bar feeder. It comes with a touch screen interface and handheld pendant. Photo credit: Edge Technologies.

The Commander 8-80 features a 7.0" touch screen control with a 500-part program storage. A hand-held controller is standard for making setups and changeovers effortless. The newly updated electronic package comes with Ethernet I/P support. Some additional features are feeding to a stop or position and operation with subspindle mode.

Related Content

-

L.S. Starrett Inspection Technology Optimizes Data Collection, Measurement

IMTS 2024: The L.S. Starrett Co. is demonstrating a range of quality control inspection technology, specifically for data collection, vision systems, measurement systems and more.

-

ECI Machine Monitoring System Analyzes ERP Data in Real Time

IMTS 2024: ECI Software Solutions features its Alora machine monitoring system for real-time analyzation of ERP data and connection between staff and the shop floor.

-

DN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.