ECI Monitoring System Provides Actionable Insights

Westec 2023: By triggering actions that reduce downtime, scraps and failure, Alora increases utilization of existing machinery and staff.

Share

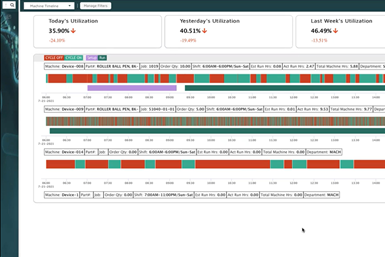

ECI Software Solutions’ Alora machine intelligence and monitoring system is designed to connect and analyze shopfloor data in real-time. By triggering actions that reduce downtime, scraps and failure, Alora increases utilization of existing machinery and staff, enabling machine operators and managers to maximize their output. ECI showcases the system in booth 1331 at Westec 2023.

Manufacturers can pull together and analyze back office and machine data in real-time. By transforming various data points into clear and attractive dashboards, all team members gain a better understanding of performance to drive behavioral changes and make business improvements. Customizable dashboards tailored to specific needs provide actionable insights, and instant access to machine performance throughout the production cycle allows for agile adjustments that enable educated decisions to be made in real time.

Alora affords manufacturers the opportunity to increase efficiency, transforming shops into data-focused and forward-thinking facilities. Identifying issues with machine insights helps managers reduce unplanned or unseen downtime by providing visibility into where and why there is an error and what next steps should be taken to resolve it.

Related Content

-

Leveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

-

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

-

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

.jpg;maxWidth=300;quality=90)