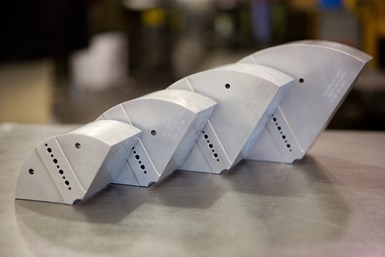

Dillon Pin Location Jaws Hold Deformation-Sensitive Parts

Dillon Manufacturing CNC mills its pin location jaws for air chucks to the highest possible workpiece location accuracy, better enabling them to hold thin-wall and deformation-sensitive parts.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Dillon Manufacturing Inc. uses CNC milling to machine its full-grip (pie) blank jaws for air chucks to the highest possible accuracy for workpiece location, enabling the chucks to firmly hold thin-wall and deformation-sensitive workpieces. The full-grip jaws fit standard in chuck sizes ranging between 4” and 10” diameters. Full-grip jaws are available in 1018 steel and 6061 aluminum, and standard jaw heights are between 1’ and 4”.

Customers can request jaw customization – experienced Dillon application engineers perform a quotation of these engineering services at no charge. Custom jaws are typically available with industry-leading lead-times of three days or less. Dillon manufactures all of its products in the USA and is ISO 9001:2015-registered.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.