Digitalization Suite Boosts Machining, Programming Efficiency

NC Reflection Studio is said to provide full machining simulation for verfication and optimization of the G-code program, job setup and part production.

Share

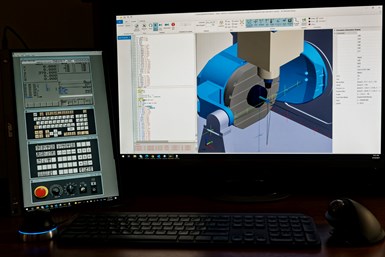

FANUC America’s NC Reflection Studio software enables complex program creation, troubleshooting and editing while simulating the cutting process.

The software uses machine models from the machine tool builder or select CAM systems with a virtualized FANUC CNC, creating a digital twin to provide powerful G-code and cutting simulation. This is in addition to backplotting, program editing and full-featured job setup. This aspect is said to provide simulation accuracy by using the real CNC parameters, machine layout and kinematics. Additionally, users can upload or download part programs to the CNC over an Ethernet connection for simple program management.

This tool helps create programs that are correct for the exact machine setup, ultimately making parts more efficiently with less risk, the company says. The simulation suite is said to enable users to spend less time testing posted programs at the machine and more time cutting.

The software also enables part program editing and complete job setup of tooling, fixtures, offset and part blanks. Importing posted programs from CAM and testing using the machine models and CNC setup enables users to see how the machine will process the program in the real world.

The online simulation is said to unlock the ability to test programs utilizing the actual machine parameter settings. With this flexibility of editing programs between the backplot, cutting and online simulation environments, FANUC says users can quickly test programs while editing to verify detailed programs before releasing them to production.

Related Content

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

.jpg;maxWidth=300;quality=90)