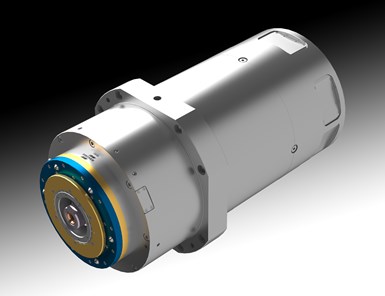

Combined Milling Head and Spindle Provide Perfect Rotation

IMTS22: Fischer’s D27 milling head, in combination with its MFW-2714/20 HSK-100 spindle, is designed for the most powerful, long-tooled milling applications.

Share

Fischer USA Inc. showcases its D27 milling head paired with its newest technology for high-volume material removal in their MFW-2714/20 HSK-100. With 80 years of experience in high-performance machine tool spindle design, in-house manufacturing and best-in-class repair services, the company presents this new design, a combination milling head-milling spindle that provides maximum stability and precision for aerospace and other five-axis machining operations.

Features on this advanced milling head and spindle combination includes perfect rotation in not only the spindle but also the milling head. This is achieved by precisely calculated mono-block structures made of high-grade cast iron paired with two cross-roller bearings for A-axis and YRT for C-axis, which reportedly provide the highest load capacity to handle the cutting forces in all directions during power milling. The unit is also said to offer machine builders and end users a robust HSK-100 interface, max speed of 20,000 rpm and an S1 continuous power rating of 200 kW.

The Fischer D27 milling head is said to be specifically designed for the most powerful, as well as long-tooled, milling applications. With the high power and torque output, the D27 milling head still maintains its sleek symmetric outline while being dynamic and robust. To ensure accuracy and repeatability, the unit incorporates direct optical encoders, dual motors and dual clamps on the A-axis. The D27 milling head is intentionally designed to utilize the maximum power and torque capacity of Fischer’s 275 mm spindles for the highest chip removal rate.

Related Content

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

.jpg;maxWidth=300;quality=90)