CNC Software Inc. Enhances Mastercam Turning Capabilities

According to CNC Software Inc., users can save time and avoid errors by creating reusable assemblies of modular components. These assemblies can be stored in a library and used for the creation of full 3D lathe tool assemblies.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

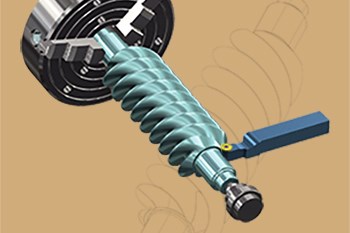

CNC Software Inc. has announced the release of Mastercam 2022 turning solutions. Mastercam 2022 offers users a variety of turning options, from accepting and programming any CAD file to Dynamic Motion roughing and precision finishing. Mastercam 2022 also features new Mill-Turn support, enhancements to 3D turning tools, stock diameter and more.

New Options for Turning

With Mastercam 2022, users can now define reusable holder assemblies, as well as create collections of adapters, extensions and holders, and store them as an assembly. According to the company, users can save time and avoid errors by creating reusable assemblies of modular components. These assemblies can be stored in a library and used for the creation of full 3D lathe tool assemblies.

When defining stock dimensions in Job Setup, a new button enables users to specify the outer or inner diameter by selecting an arc or radial face. After choosing a selection, users are returned to the graphics window to select an arc or radial face, as well as an edge. Mastercam reportedly can automatically read the proper diameter value from the selected geometry.

Extended Support for Mill-Turn

CNC Software Inc. says Mastercam 2022 introduces steady rest support for Mill-Turn, which enables users to precisely position and simulate steady rests throughout the machining process, adding part support capability to turning, milling and part-handling operations. This includes new component types, enhanced component libraries, dedicated operations for each type of steady rest, part handling strategies and simulation features.

The subprogram support that has been in other Mastercam products has also been added to Mill-Turn, enabling users to create subprograms for depth cuts and hole making operations such as drilling. In addition, users now have the option to have Mastercam automatically retract the center when creating a center point operation in Mill-Turn.

Swiss Machining Solutions

Mastercam’s Swiss Solution also receives improvements and updates to Mastercam Lathe, including expanded options and more efficient programming, combined with Mastercam Mill, to provide fast, user-friendly Swiss programming.

Related Content

-

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

.jpg;maxWidth=970;quality=90)