CNC Simulation Software Uses Data for Smarter Manufacturing

The latest version of CNC simulation software incorporates enhancements and new features focusing on using data for smarter, more informed manufacturing.

Share

Photo Credit: CGTech

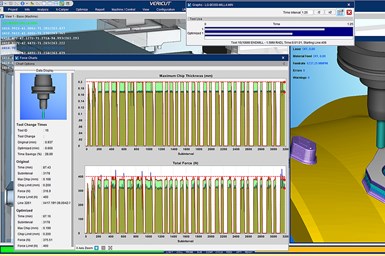

CGTech’s Vericut 9.3 is the latest version of its CNC simulation software, which is focused on establishing smarter, more efficient manufacturing processes by incorporating data from the machine, tools and stock material to improve the quality of the simulation and enable more informed decisions throughout the manufacturing workflow.

The software is said to include improvements to its core features, including improved collision checking, higher limits on axes per subsystem and more. Some of the improvements benefit additional, optional modules such as those for additive simulation and optimization, the company says. With the additive module, shops can simulate, validate and verify NC programs in any order of additive and traditional machining to ensure that all setups and holding fixtures will work. The software verifies laser activity, power, material feed and gas flow to prevent voids and misplaced material, while preventing collisions between the hybrid machine with the additive part.

The software’s Force optimization module has also received additional features and enhancements, with improvements to deflection calculations and the ability to add volume removal rates (VRR) as a limit during optimization for traditional, subtractive machining operations.

Related Content

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.