Cetec ERP System Prevents Slowdowns in Production

The Pre-Allocation feature simplifies the purchasing and material planning process and prevents unnecessary inventory from sitting on the shelf.

Share

Cetec ERP’s Pre-Allocation inventory management feature is tailored to contract manufacturers in any supply chain vertical to help with managing inventory across multiple projects or programs.

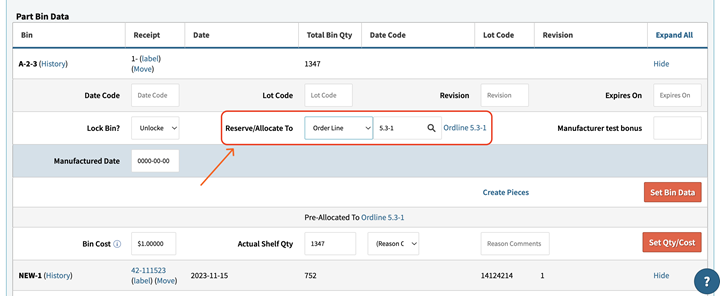

The Pre-Allocation feature facilitates the early assignment of materials to specific projects and customers, enabling users to designate a customer or work order directly on the supplier’s purchase order or existing on-hand inventory. The tool ensures that customer-supplied inventory is not shared, and that work orders have appropriate inventory allocated to prevent slowdowns in production. By allowing early inventory assignment, contract manufacturers can address key inventory management challenges, such as preserving customer-supplied inventory for the right jobs, material planning for large projects and programs as well as protecting estimated costs.

For job shop contract manufacturers, Pre-Allocation simplifies the purchasing and material planning process and prevents unnecessary inventory from sitting on the shelf. Large projects can have purchase orders quickly placed and pre-allocated to the job, reducing overhead while also protecting the production schedule and critical need dates.

Pre-Allocation also simplifies material planning and strengthens inventory oversight, ensuring that materials are dedicated to intended projects ahead of production, streamlining operations and enhancing project delivery accuracy.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

.jpg;maxWidth=300;quality=90)