Bystronic Introduces High-Powered 15kW ByStar Fiber Models

Bystronic has launched its ByStar Fiber 3015 and 4020, which include a new, high-powered 15kW laser for enhanced power and productivity.

Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

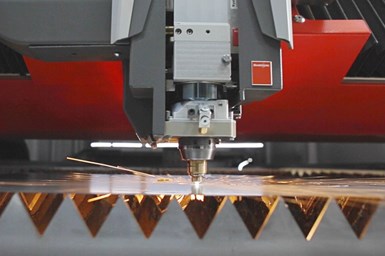

Bystronic is moving into the high-powered fiber laser cutting market with the 15kW ByStar Fiber. Bystronic says the ByStar Fiber laser presents a high-precision, reliable cutting process even at the highest laser outputs.

On average, the new 15kW laser allows the ByStar Fiber to achieve a cutting speed up to 50 percent faster when cutting with nitrogen compared to a 10kW laser source. This increases sheet metal processing companies’ productivity with relatively low unit costs. The 15kW laser output also enables extended applications in stainless steel and aluminum up to 1.5” thick, with brass and copper applications up to .750” thick.

The company says the machine's high-performance Bystronic SSC cutting head attains maximum precision in both thin and thick sheets and profiles. The variable telescoping cutting head automatically adjusts the focal length and spot size, and the focal position is set automatically for each material.

Bystronic also says the BeamShaper function ensures smooth cutting edges and high operational reliability across the entire range of carbon steel materials with fluctuating material characteristics to thicknesses up to 1.125”. This function is available as an option when purchasing a new 15kW ByStar Fiber or can be added later as an upgrade. BeamShaper optimizes the beam profile for cutting thicker materials, providing for smooth cutting edges and increased speeds in carbon steels from .750” to 1.125”.

The new 15kW power level is available for the ByStar 3015 and the ByStar 4020. Bystronic’s new high-performance flagship utilizes the ByVision Cutting control interface via a 21.5” touch screen.

Automation solutions available for the ByStar Fiber include loading and unloading systems, sorting solutions and individually configurable storage systems. The company says its options adapt to the existing manufacturing environment and available space to create a seamless automated laser cutting process.

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

.jpg;maxWidth=300;quality=90)