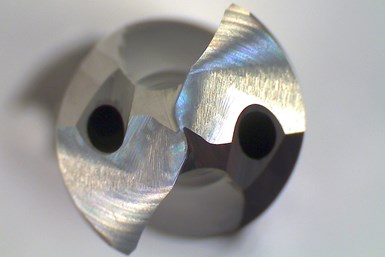

Better Edge's Drill Point Features Unique Geometry

PMTS 2023: The Bat Wing point geometry provides optimized gashing for lower thrust, polished flutes for increased chip evacuation and coolant gash channels for optimum flow.

Share

Better Edge’s Bat Wing drill point geometry is designed for machining steels, stainless steels and irons. The patented point geometry features optimized gashing for lower thrust, polished flutes for increased chip evacuation and coolant gash channels for optimum flow, as well as a radius edge for edge strength and centering capabilities.

A proprietary edge preparation process and high-performance AlTiN coating yield greater tool life and improved process performance. According to Better Edge, recondition performance is like new, offering users optimal drill life and cost savings. Better Edge is an ISO 9001:2015-certified company located in Scottdale, Pennsylvania.

Related Content

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

.png;maxWidth=300;quality=90)