ANCA Grinding Solution Provides Flexible Five-Axis Machining

The TX7 Linear and TXcell Linear provide flexibility in the applications that can be put through it than other three-axis grinders more traditionally used for punch manufacturing.

Share

ANCA’s TX7 Linear is a five-axis grinding machine used for punch manufacturing. According to ANCA, this machine offers greater flexibility in the applications that can be put through it than other three-axis grinders more traditionally used for punch manufacturing. A traditional punch grinding machine would have been capable of grinding only the outside form of the punch with a single wheel, whereas the TX7 Linear is capable of more.

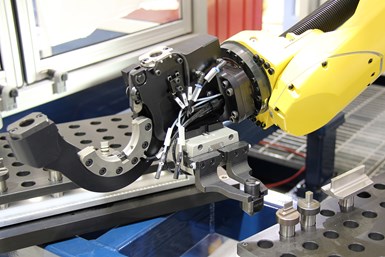

The TX7 Linear features two-wheel packs, and the company’s TXcell robot offers anywhere from nine- up to 24-wheel packs, meaning a range of operations can now be done in a single setup. Aside from changing wheel packs, the TXcell robot can also be used for automated loading of tools, which means it supports unattended shifts. Having more than one wheel pack on the machine brings other benefits too. By using different roughing and finishing wheels, grinding operations can now be optimized for stock removal or fine surface finish.

The TX7 Linear and TXcell Linear are also said to be ideally suited for the use of CBN grinding wheels. Using a much smaller wheel diameter (up to 200 mm / 8" on TX7 Linear and 300 mm / 12" on TXcell Linear), CBN provides optimized grinding feed rates and requires less frequent wheel dressing. The TX7 Linear and TXcell Linear machines can reportedly grind punches within 2-3 µm with a surface finish of less than 0.1 Ra.

The TX7 Linear and TXcell Linear also enable the production of keyhole punches. These punches typically feature much more complicated OD profiles, including concave forms, and require a fundamentally different approach to grinding them. Small diameter wheels with form profiles and run at high rpm, which ANCA says the TX Linear machines can handle with ease.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.