Allied Machine's T-A Pro Drills Improves Holemaking

Allied Machine recently announced the T-A Pro spade drilling insert as a new high performance go-to for general purpose holemaking.

Share

Allied Machine and Engineering’s high-penetration drilling system, the T-A Pro is designed to heighten performance in its “go-to” solution for general purpose holemaking.

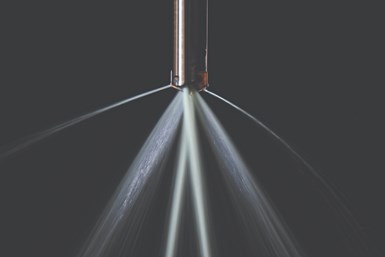

The drill combines material-specific insert geometries, a redesigned drill body and a proprietary coolant-through system intended to allow penetration rates the company says are nearly 30% faster than other high-performance drills. Coolant outlets are designed to direct maximum flow to the cutting edge, providing quick heat extraction even at significantly higher speeds. Material-specific insert geometries produce quality chip formation, while the drill body incorporates straight flutes redesigned for maximum coolant flow and rigidity. According to the company, these design elements will extend tool life, create consistent quality holes and provide superior chip evacuation, combining to a cost per hole averaging 25% less than existing drills.

The T-A Pro drilling system is available in diameters ranging from 0.4370" to 1.8820" (11.10 to 47.80 mm) and is suitable for holes with stub, 3×D, 5×D, 7×D, 10×D, 12×D and 15×D depths. Drill variants include imperial and metric shanks with flat and cylindrical designs. The carbide insert geometries offered initially will cater to the following ISO material classes: steel (P), with AM300 coating; cast iron (K), with TiAlN coating; and non-ferrous (N), with TiCN coating.

Related Content

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.