Products

High-Speed Machining Process Uses Continuous Tangential Movement

Gibbs & Associates now includes VoluMill Wireframe within its GibbsCAM Production Milling software.

Read MorePaper Bed Filters Control Bacteria Contamination

PRAB’s standard and magnetic paper bed filters are said to control bacteria contamination and extend coolant and tool life while increasing surface finish by an average of 27 percent.

Read MoreManual Vertical Knee Mills for Job Shops, Tool Rooms

Sharp Industries’ manual vertical knee mills are equipped with a 3-hp R-8 spindle, precision spindle bearings and Meehanite castings.

Read MoreVMC Enables Unattended Operations

Mazak’s Variaxis i-700 vertical machining center accurately processes long parts as well as those with complex profiled surfaces in single setups.

Read MoreHMC Offers Flexibility in Cutting Capabilities

Kitamura Machinery’s Mycenter-HX500G horizontal machining center, part of the company’s G series of machining centers, is designed for medium to large parts that require flexibility in cutting capabilities.

Read MoreVMC Designed for Job Shops

The VMC850E vertical machining center from SMTCL Americas offers a compact layout, large side doors and extended axis travels, making it particularly well-suited for use in small job shops, the company says.

Read MoreHMC Designed for Faster Cycle Times

OKK’s HMC500 horizontal machining center features a 500-mm pallet to accommodate large workpieces and is intended to provide faster cycle times.

Read MoreFive-Axis Machining Center for OEMs, Job Shops

Available from Methods Machine Tools, the Methods-Yasda PX-30i is a five-axis high-precision automated vertical machining center designed to meet OEM and job shop requirements.

Read MoreFive-Axis HMC Equipped with Work-Pallet Magazine

Makino’s a51nx-5XU five-axis horizontal machining center incorporates a fifth-axis table and work pallet magazine, and is intended to serve as an alternative to single-pallet-load vertical machining centers for machining of small parts.

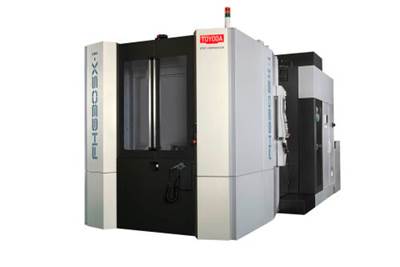

Read MoreHMC Enables Aggressive Cutting of Large Workpieces

The FH630SX-i horizontal machining center from Toyoda Machinery USA is a 630-mm-sized linear guideway machine that offers a standard 8,000-rpm spindle providing 37 kW (1,009 Nm) of torque and features dual ballscrews on the Y and Z axes.

Read MoreTwo-Spindle HMC for Four- and Five-Axis Machining

SW North America’s BA 322 is a compact, twin-spindle horizontal machining center designed for four- or five-axis machining of small to medium-sized steel, cast iron and light-metal workpieces.

Read MoreVMC Enables Lean Small-Part Production

Enshu USA’s GE300Ve vertical machining center is specifically designed for efficient production of small parts in a lean line.

Read More