ThinkIQ Launches Open Software Platform for Smart Manufacturing

Through a partnership with the Clean Energy Smart Manufacturing Innovation Institute, ThinkIQ is expected to deliver a simpler, lower cost and more effective implementation of smart manufacturing solutions to solve manufacturing problems.

Share

Autodesk, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ThinkIQ, a leader in digital manufacturing SaaS (software as a service), announces that the Clean Energy Smart Manufacturing Innovation Institute (CESMII), the United States’ national institute on Smart Manufacturing, will now be licensing its technology to power CESMII’s Smart Manufacturing Innovation Platform (SMIP). The CESMII SMIP is said to be positioned to drive adoption of smart manufacturing more broadly in the United States through powerful open interfaces. According to ThinkIQ, democratized information models make it easier, faster and cheaper than traditional closed solutions available to the manufacturing community.

With ThinkIQ as the foundation of the CESMII SMIP, ThinkIQ customers will be able to benefit from smart manufacturing applications developed and integrated with the SMIP and CESMII’s further development and expansion of smart manufacturing profiles. ThinkIQ says this will enable a simpler, lower cost and more effective implementation of smart manufacturing solutions to solve manufacturing problems as offered in CESMII’s Smart Manufacturing Marketplace. This open platform is designed to enable a new generation of app developers, data scientists and operators to create and explore new ways of understanding manufacturing problems.

ThinkIQ’s SaaS Manufacturing cloud-based platform is said to simplify the creation of web-based applications and leverage the strengths of the Internet of Things (IoT), Big Data, data science, semantic modeling and machine learning. The platform collects data across the operation (existing and IIoT sensors) to provide actionable real time insights (for example, to identify correlations and root causes, traceability and yield issues).

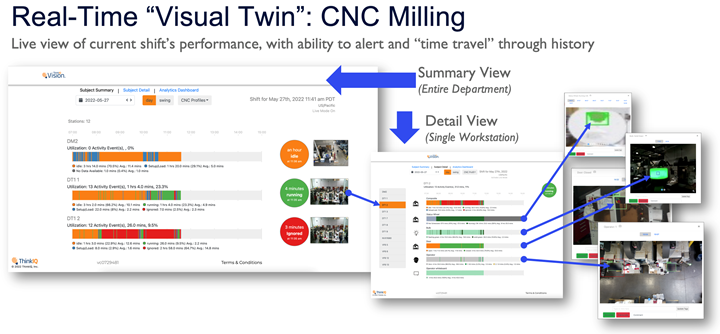

ThinkIQ’s recently enhanced Vision platform provides unparalleled visibility on the shop floor, eliminating blind spots and increasing productivity and worker safety. This is said to create a new level of capability beyond what independent disconnected operating environments can provide today, helping companies to manage their manufacturing operations and supply chains more effectively during economic disruptions and labor shortages.

Related Content

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

-

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.