LK Metrology Releases Updated CMM Software

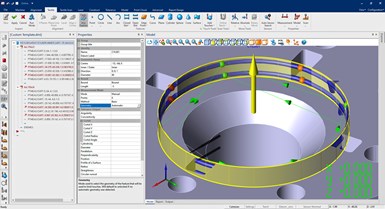

Camio 2021 features increased inspection productivity, improved quality of data collected and better insight into the components being measured. Virtual CMM programming enables accurate axis movement and probe motion sequences to be simulated.

Share

LK Metrology has announced the release of the latest version of its measurement, programming, analysis and reporting CMM software. Now called Camio 2021, the software reportedly features increased inspection productivity, improved quality of data collected and better insight into the components being measured.

According to LK Metrology, Camio 2021’s Geometry Validation feature automatically detects which surfaces of the CAD model should be used to measure the feature. The company says this ensures that all measurements are taken on suitable surfaces automatically and provides the programmer with the option to modify the default settings and selections. The CAD simulation, combined with the Teach Path view, provides a full visual and numerical evaluation of the programming sequence prior to executing the touch points or scanning sequence.

Camio 2021 also features probe self-centering, which enables the center point of a V-groove to be automatically located and measured using a scanning probe. Probe self-centering responds to the continuous deflections of an analogue probe in real time to locate the mid-point between two surfaces.

In addition, Camio 2021’s Orientation Tolerancing automatically determines the appropriate relationship to a secondary datum based on the nominal feature definitions. Tolerance zone shape and relationship to the secondary datum outputs have been added to enhance the output of orientation tolerances. Perpendicularity, parallelism and angularity checking have been enhanced for geometric dimensioning and tolerancing (GD&T).

According to the company, an advanced user interface makes part alignment, feature inspection and dimensional tolerancing fast and intuitive. The virtual CMM programming environment enables accurate axis movement and probe motion sequences to be simulated for collision detection and cycle time estimations.

For CAD users, the Camio 2021 exchange file versions have been updated to the latest release of Spatial's InterOp. The interoperability software enables users to import, interact with, share and export 3D data across CMM platforms and manufacturing sites.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.