Jorgensen Partners With Will-Fill on Coolant Management System

Will-Fill’s automatic coolant monitoring and managing systems are now featured on Jorgensen’s filtration systems.

Share

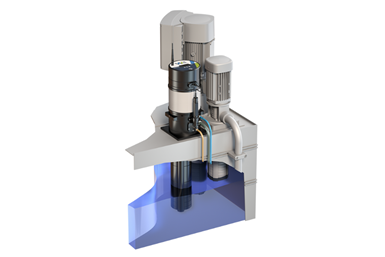

Jorgensen Conveyor and Filtration Solutions has entered into a partnership with Will-Fill, a manufacturer of fully automatic coolant monitoring and managing systems. The strategic partnership enables Jorgensen to offer customers coolant management systems, such as the company’s recently launched PermaClean, that provide both filtering and measuring capabilities for an all-in-one solution.

With the addition of the Will-Fill add-on device, a coolant system can provide trouble-free care of metalworking emulsion by combining automatic measurement and analysis of fluid with faultless filling, permanent conditioning and timely reporting, according to Jorgensen. The Will-Fill components are linked to a high-performance control unit, enabling the device to regulate and adjust the fluid level and the fluid condition automatically. Additionally, it can alert users when attention is necessary via WiFi or LAN network capability.

Will-Fill can be combined with Jorgensen’s filtration options, such as PermaClean. Coolant tanks equipped with PermaClean are designed to eliminate tank sludge, reducing the labor required for frequent tank cleaning. When combined with the cyclonic filtration option and a Will-Fill, the system is said to be fully automated and nearly maintenance free.

Will-Fill units are field retrofittable and can be added to almost any machine tool coolant tank.

“At Jorgensen, our goal is to provide customers with systems that make coolant management an invisible process within their machining operations,” Karl Kleppek, president and COO at Jorgensen, says. “The combination of PermaClean and Will-Fill to our FlexFiltration systems portfolio uniquely positions us to deliver complete, fully automated, maintenance-free conveyor and filtration solutions — allowing users to return their focus to machining.”

Related Content

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.