Hexagon Pre-Loads Star Cutter Grinders with CAM Software

The packaged solution is aimed at assisting manufacturers of complex medical tooling, such as hip rasps, rotary files, bone files and drills.

Share

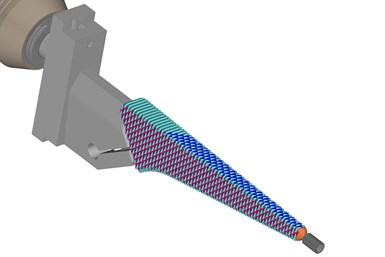

Star Cutter Company and Hexagon Manufacturing Intelligence have established a partnership that enables the Star Cutter NXT five-axis grinders to be sold with a seat of pre-loaded Espirit CAM software. This packaged solution is aimed at assisting manufacturers of complex medical tooling, such as hip rasps, rotary files, bone files and drills.

The NXT grinder is a five-axis CNC machine with a small footprint, large grind zone and a modular design. Espirit uses a digital twin of the manufacturing envelope to simplify the programming process and deliver G code. Customers that already have Espirit can reportedly add the Star Cutter NXT’s digital machine package to their existing license and program the NXT using the software they already own.

“This is our first formalized partnership with a grinding company,” says Vytas Cijunelis, Espirit’s Midwest operations manager. “And Star Cutter was the right choice for us given the NXT’s grinding capability and their team’s process knowledge in producing medical tooling. We look forward to expanding our footprint in this market.”

Star Cutter will feature an NXT running Espirit software for demonstration at its Elk Rapids, Mich. facility. Video and remote demonstrations are also available.

Related Content

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.