Beaumont Machine Provides Small Hole EDM to SpaceX

The new Beaumont small hole machine at SpaceX – a new customer for Beaumont Machine – has a reach of eight feet in diameter and eight feet in height.

Share

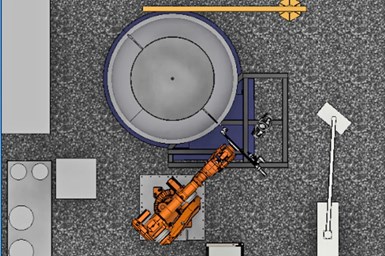

Beaumont Machine, a supplier of fast hole and small hole electrical discharge machines (EDM) for the aerospace industry, has provided service to market leaders such as Lockheed Martin, Pratt & Whitney and General Electric for over 20 years. Recently, the company supplied a new small hole EDM to SpaceX, a new customer for the company. The new Beaumont small hole machine at SpaceX has a reach of eight feet in diameter and eight feet in height.

Company president Ed Beaumont notes, “As the needs in the industry are changing, we’ve made changes to keep pace. For the past three years, Beaumont Machine has been working with the advanced CNC control systems from Siemens to support the real-time connection to our power supply. This has improved our hole shape technology, breakthrough rate and overall holemaking process quality. We just completed a project with SpaceX, using this newly developed control system in tandem with integrated large ABB robotics for positioning of the electrode.”

Related Content

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

.jpg;maxWidth=300;quality=90)