Machining Titanium Aluminide at AeroEdge

Japanese manufacturer AeroEdge has had success in machining turbine blades from challenging TiAl through a combination of customized VMCs and cutting tools designed in house.

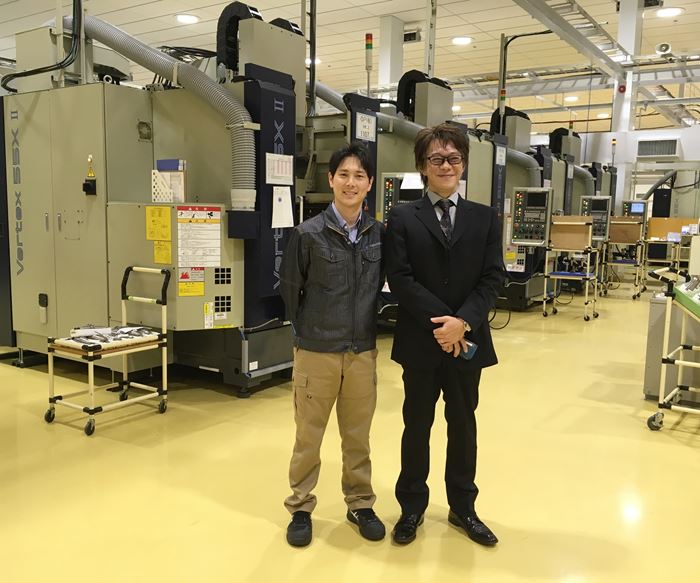

“Progressive and disruptive” is how Robb Hudson, CEO of Mitsui Seiki (U.S.A.) Inc., characterized AeroEdge during a visit to the aerospace manufacturer’s facility in late 2017. The startup is located in Japan, where manufacturing tends to be conservative, and Mr. Hudson’s description was meant, in part, to underscore what sets the company apart in its geographic region.

But what AeroEdge is achieving in aerospace manufacturing could be considered progressive and disruptive for any part of the globe. Using a mix of customized equipment (including Mitsui Seiki machine tools), a tooling program developed in house and advanced inspection techniques, the company is one of just two manufacturers in the world providing the titanium aluminide low-pressure turbine (LPT) blades used in the Leading Edge Aviation Propulsion (LEAP) jet engine.

Breaking into Aerospace

AeroEdge is a young company in more ways than one. Registered in 2015, the business is staffed by some 70 employees with an average age of just 32, although the startup is actually a subsidiary of Kikuchi Gear, a traditional Japanese heavy-industry company with strong ties to the automotive industry as well as experience in providing a range of aerospace parts for large OEMs. AeroEdge was launched with a more specific mission: the manufacture of next-generation aerospace parts.

The subsidiary has just one major customer, Safran, and is focused primarily on the manufacture of LPT blades with some R&D work mixed in. It's unusual for a small to medium-size manufacturer like AeroEdge to have a direct relationship with a global OEM like Safran, especially in Japan, notes Jun Morinishi, president and CEO. However, he says the backing of its parent company plus a creative and strategic attitude about technology innovation has helped AeroEdge to win and keep this business.

As the result of this relationship, AeroEdge has cultivated a core competency in processing titanium aluminide (TiAl), the material used for the LPT blades. The material’s rigidity and stiffness lends itself to small aerospace parts such as these blades, Mr. Hudson explains. Titanium aluminide is stronger and lighter than titanium, but with a grain structure that makes it brittle and difficult to machine.

Fitting the Equipment to the Application

AeroEdge receives pre-certified TiAl forgings for single turbine blades directly from Safran at its 107,640-square-foot factory in Ashikaga, a city located northwest of Tokyo in Japan’s Tochigi prefecture. The facility’s equipment was installed in December 2016, and most of it has customized features for manufacturing these specific parts.

The forgings are first roughed using customized waterjet systems. Each of the five systems features a high-pressure (600-megapascal) waterjet cutting head from Aquarese by Flow mounted on a robot arm to enable five-axis cutting. A specialized cutting abrasive is used to help achieve accuracy in the tough titanium aluminide.

From there, one of the company's 25 Vertex 55X-II five-axis vertical machining centers from Mitsui Seiki removes the striations left by the waterjet process and finish-machines the parts. These machines were selected because AeroEdge wanted to work with a Japanese machine tool builder, and the Vertex platform met the startup’s requirements for accuracy, a compact (6-square-meter) footprint and automation readiness.

But perhaps more important was Mitsui Seiki’s willingness to collaborate with AeroEdge to develop a version of the Vertex optimized for machining single TiAl LPT blades, including an internal configuration modified from the standard arrangement. Rather than trunnions oriented parallel to the machine door, as is standard, AeroEdge’s machines have trunnions oriented perpendicular to the door, situated to the left side of the envelope. The space in the envelope left open by this configuration can be used for sequential fixturing. Dual servomotors for each side of the rotary axis ensure equal torque to prevent twisting of the blade during machining. The VMCs support spindle speeds ranging to 25,000 rpm, with fast acceleration and deceleration that enables rapid reversal during the milling process.

"They listened to our voice," says Kazuhiro Mizuta, AeroEdge chief technology officer, citing Mitsui Seiki’s willingness to work with his company to develop a machining center just for this application. This machine configuration is now commercially available in the Vertex 500 platform, and will soon be offered for the 750 platform as well.

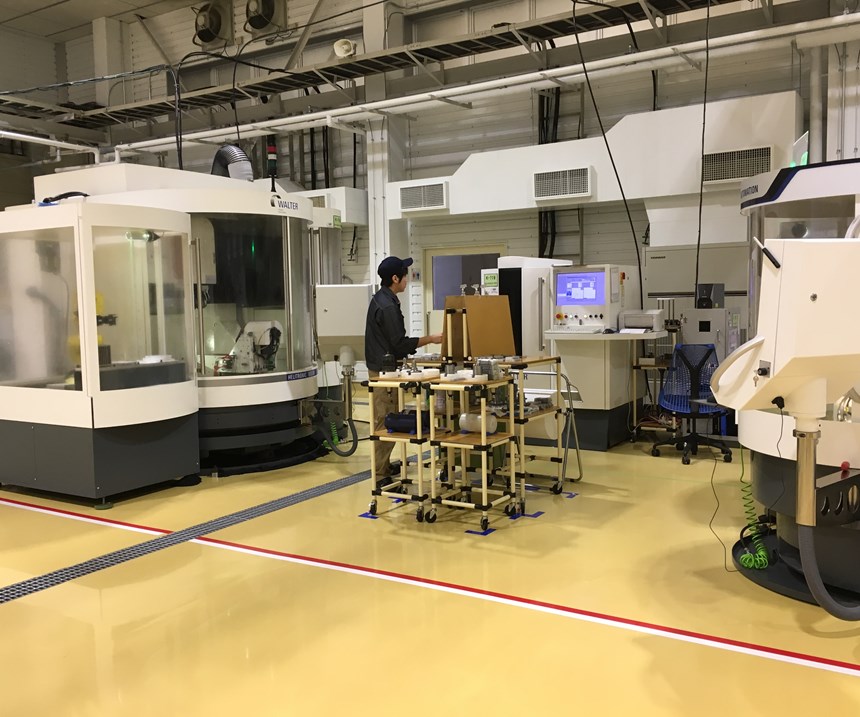

Tooling is also critical to AeroEdge’s success in processing titanium aluminide, as very sharp tool edges are necessary to ensure that the grains cut evenly. The company designs all of its own cutting tools and manufactures many of them in house from a specialized superalloy carbide material. In-house tool production takes place on two Walter Helitronic tool-grinding machines, each equipped with a FANUC robot for loading/unloading. A Helicheck inspection system checks one in every five or 10 tools.

AeroEdge runs two shifts just for cutting tool production but sometimes also outsources this work, providing the designs and raw material to outside manufacturers. Some tools receive a coating to extend their lifespans, also done out of house.

Multi-Stage Inspection

After machining, the LPT blades are ground smooth on Nagase Integrex SHR-15 grinding machines and checked for dimensional accuracy using an automated Mitutoyo coordinate measuring machine. But this is just the first step in a three-part inspection process.

Blades then travel down AeroEdge's fluorescent penetrant inspection (FPI) line, an inspection process certified by Safran that helps to identify surface defects. The parts are immersed in a tank of fluorescent dye that etches the surface. A certified technician then checks each part under a black light for blemishes, and any issues that are discovered must be reported back to Safran.

Finally, an operator loads the blades into a jig for inspection on an Yxlon MU56TB digital X-ray inspection system, the only one of its kind in Japan, Mr. Mizuta says. The process can take five minutes per blade, but every blade is checked for internal defects before they are packaged and shipped to Safran.

The Ashikaga plant is not operating at full capacity, but AeroEdge has plans to add equipment to meet Safran's demand as the LEAP engine grows increasingly popular for its efficiency and low maintenance costs. Future upgrades to the factory could also include automated doors for the Vertex machines and robot loading/unloading. Machine monitoring and other “smart factory” improvements may follow.

Future expansion will depend, at least in part, on finding other suppliers willing to adapt equipment to the company’s needs. Additive manufacturing (AM) is one area of interest, for its potential in maintenance repair and overhaul (MRO) applications, lightweighting and assembly consolidation in aerospace and other industries. The challenge there, Mr. Mizuta says , would be not just selecting the right system and process (likely candidates might be powder-bed fusion or wire-fed direct energy deposition), but also finding a supplier offering an AM-ready powder or wire in titanium aluminide, the material that AeroEdge knows best.

Related Content

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Read MoreRomi Launches Flatbed Lathe for Machining Large Parts

The C 1100H is a heavy-duty flatbed lathe built with a monoblock cast iron bed that absorbs machining efforts and vibration, making it highly rigid, stable and accurate.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreSpindleSHOT Offers Improved Chip Control and Less Maintenance

High-pressure coolant system is customizable to meet customer needs.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read More

.jpg;width=70;height=70;mode=crop)