For CNC machining fixtures, “automation” means more than just eliminating manual clamping. With a hydraulic workholding system, pressure feedback from strategically placed air orifices can provide a simple, effective means of saving time and ensuring process consistency and reliability. Generally, these systems perform three functions: verifying whether clamps have moved into position, verifying whether parts have been loaded correctly, and verifying whether the right parts have been loaded in the right fixtures.

Self-validating hydraulic workholding can act as a check on human machine tenders. However, if robots are doing the loading, such capability can be essential, says Scott Bower, partner at custom fixture supplier DMT Workholding. “One cost of replacing the human is that you lose judgment, and that’s what these kinds of fixture features replace,” he explains. “They confirm things that you’d normally be counting on an operator to validate.” As for which manufacturers benefit most, “It could be the Ma-and-Pa shop or GM. If they’re running lights out, they have to have this kind of feedback to ensure that they’re making good parts and protecting their equipment.”

DMT is getting more opportunity to provide this kind of feedback because increasing numbers of customers see automation as the answer to skills shortages and competitive pressures, he says. In some plants, machine-tending arms on rails are replacing pallet-carting vehicles on rails as high-volume work leads manufacturers to abandon their linear pallet systems. Robots are also replacing people on a smaller scale, as is the case in cells that consist of a single six-axis arm and just a few machine tools. Meanwhile, these DMT customers have come to view pressure-sensing feedback as a basic and essential feature of any new hydraulic fixture, Mr. Bower says. “In the past, tying in this kind of feedback to a CNC or robot controller would have required a controls engineer and in-depth integration. Now, this capability has become default on most machines.”

Safety in Simplicity

One attraction of pressure-sensing feedback is simplicity, he says. Everything required to validate that the fixture is operating properly is contained within the fixture itself. For a CNC machine shop, these systems provide three safeguards:

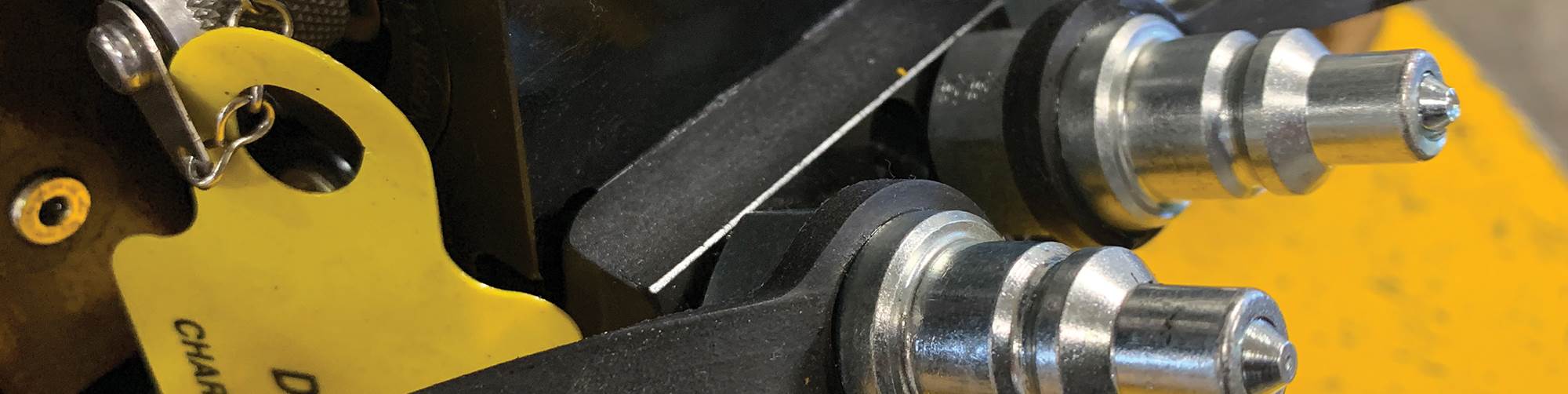

- Part-seat confirmation. Pressure readings from strategically placed air orifices can indicate whether a part is mounted properly in the fixture. If not, the robot can place the part elsewhere and continue its routine, or the operator can be alerted to fix the problem.

- Clamp-rotation confirmation. Pneumatic pressure sensors can determine whether individual clamps have rotated fully to their closed and/or open positions. This can be particularly important in cases when close-quarters machine motion risks collisions between tools, fixtures and parts, Mr. Bower says.

- Part Validation. Some fixtures can hold two different parts because they have identical patterns for datum-clamping locations. In this case, pneumatic switches can be employed to differentiate parts and ensure the right one is loaded before machining begins.

The Value of a Live Connection

Generally, the greater extent to which the same or similar parts can be run on the same fixtures and machines, the greater the opportunities and rewards associated with self-validating fixtures. “If the volume is there, automation is typically easier to justify,” Mr. Bower says.

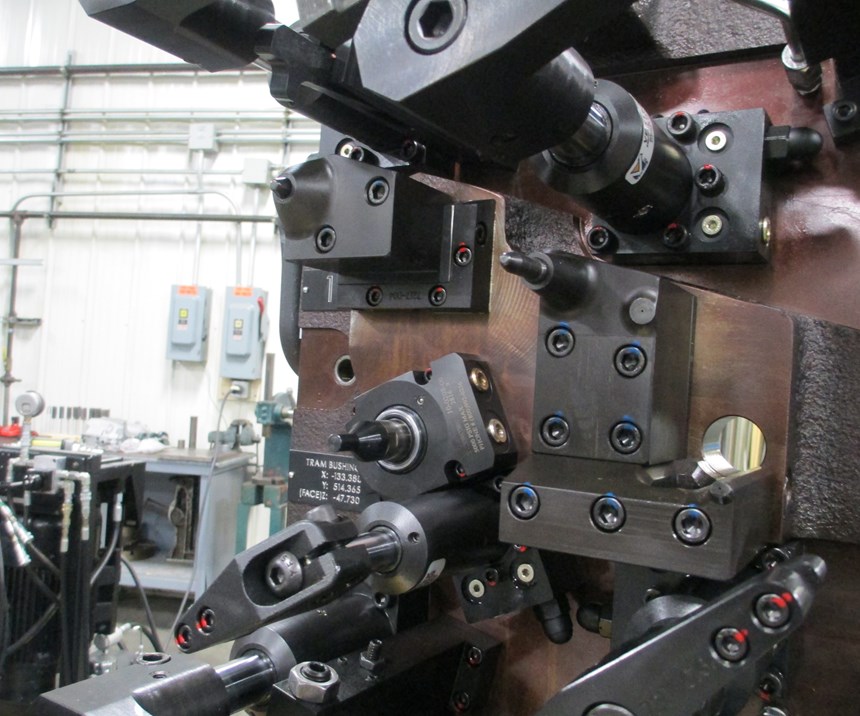

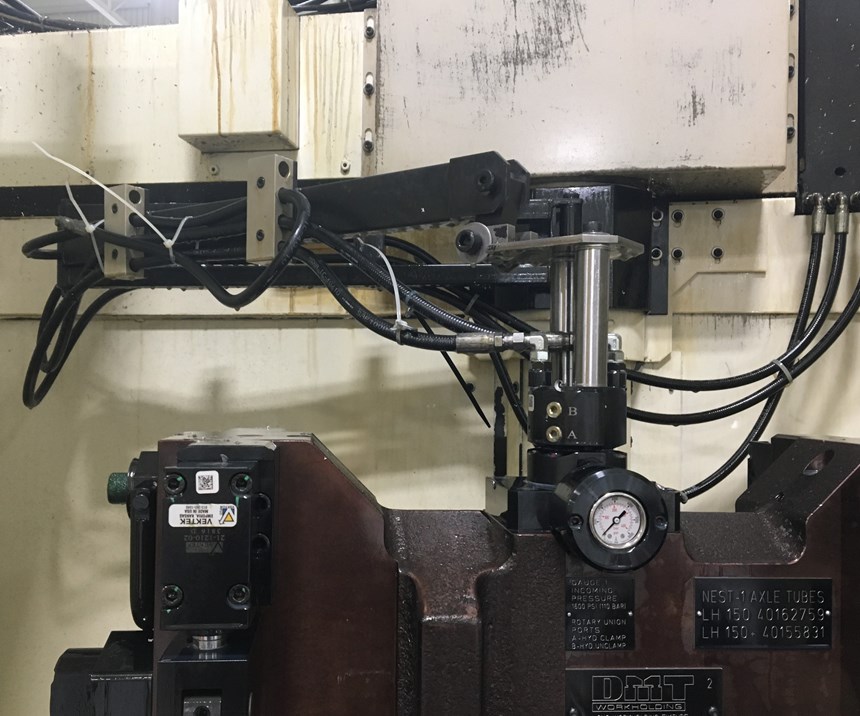

The reason why is because high-production applications make it practical to dedicate fixtures to machines. A “live” connection—that is, a direct link to the CNC and a steady supply of hydraulic fluid and air—is a significant advantage to adequate clamping pressure and to implementing features like part-seat confirmation, he says. With a VMC, the solution can be as simple as threading cabling unobtrusively through the workzone. However, the HMCs prized by many manufacturers that run lights out require rotary unions and articulator arms to manage the hoses.

However, rotary unions can be complex, and they require regular maintenance. What’s more, dedicating fixtures to machines isn’t an option for manufactures that require flexibility. For instance, some operations employ linear pallet systems, otherwise known as flexible manufacturing systems (FMSs). In these systems, robot-guided vehicles (RGVs) cart fixtures loaded by people to any one of a number of interchangeable machine tools as scheduling demands. For these users, DMT often recommends units like the Vektek Guardian system, a hydraulic pressure monitor that can detect pressure loss that might have occurred in the time between loading the fixture and moving it into the machine tool. However, pressure feedback beyond that—including features like part-seat confirmation—is generally impractical without a live connection.

However, these manufacturers have another option in pallet-coupling systems, which provide a direct live connection once the fixture is in position. Fixtures can be removed and replaced easily using robotic carts, hoists or any other method. “You get the best of both worlds: live hydraulics and the fixture elements we’re discussing, and also the flexibility of moving fixtures in and out of machines,” Mr. Bower says.

No Probing Required

Self-validating workholding provides more than an essential check on people and automation. “A big thing that we talk about on a daily basis is how these elements we’re building into the fixtures remove or reduce the amount of on-machine touch probing that’s required,” Mr. Bower says.

Among the more commonly eliminated probing cycles are those used to ensure parts are located properly in the fixtures, particularly in cases where access is difficult. In other cases, probes are employed to ensure that part, fixture and program all match before machining begins. “We’re eliminating probing cycles on a regular basis,” he says. “So much of it is dead spindle time—there’s no value added.”

What’s worse, probing inefficiencies are often baked into manufacturers’ processes. “Say a hydraulic fixture clamp on an HMC tombstone doesn’t move out of the way in time for whatever reason, and a $5,000 PCD-brazed cutter gets fried,” he says about hypothetical scenario. “After getting yelled at for blowing the tooling budget, the manufacturing engineer or the machinist might start running a probing cycle to verify that the clamp is out of the way even though it was a one-in-a million scenario and the collision isn’t likely to occur again. Fast-forward two years, and the employee who made the fix has moved on. That shop is still spending 15 to 20 seconds of probing time on every cycle just to verify that it won’t happen again. There’s just no need for this sort of thing. A correctly designed fixture can do it with zero spindle time.”

Related Content

Made in the USA - Season 1 Episode 2: The Automation Puzzle

There is a fundamental question we need to answer when we talk about automation: To what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreRead Next

Vertical Machining Cells Challenge Horizontal Dominance

When part volumes are high, and success is measured in pennies and seconds, moving away from horizontal machines requires creative thinking about robotics, cutting tools, workholding and more.

Read MoreRego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)