Deep-Hole Drilling Automation Is More Than Part Load/Unload

Automation inside deep-hole drilling machines can be more valuable than part handling outside of them.

Share

For deep-hole drilling, part-handling might be the most visible automation element, but it’s not necessarily the most impactful. Often, it’s internal process automation that yields the most significant results even with a manually loaded drilling machine.

When it comes to automating deep-hole drilling, there are challenges unique to the process itself. These include fixturing complexities — where maintaining alignment requires elements such as guide bushings and tool supports not present in a conventional lathe or milling machine — and part attributes such as length and weight.

Long parts mean a long drilling cycle time, and maintaining production rates often requires multi-spindle, deep-hole drilling systems. Unfortunately, stopping a two- or four-spindle machine means two or four spindles sit idle until the parts are loaded and unloaded. So, in these instances, the more parts in the machine at one time, the more automation can actually inhibit cycle time while the machine is running.

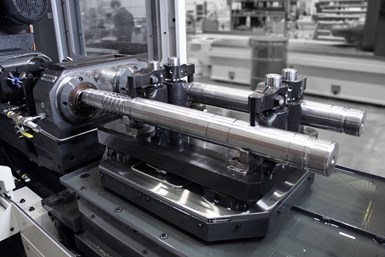

Custom part clamping facilitates high-production deep-hole drilling.

Solving this problem in multi-spindle machines requires internal automation to achieve the objectives of lean manufacturing and one-piece flow. In-machine loaders singulate processes so that even within a small four-piece batch you maintain one-piece flow. The operator or automation device puts in a part and takes a part out, and the machine does a bit of maneuvering inside to sequence those four parts in such a way as to minimize spindle downtime while maintaining upstream and downstream processes for one-piece flow. For instance, parts could be loaded onto a smart conveyor, indexed, and lifted into chucks for the drilling cycle before robotic unloading on the out-feed side so that there are no bottlenecks to a steady production flow.

Tool life management is another form of internal automation. Getting feedback to the machine enables the deep-hole drilling process to adapt or halt, if necessary, before tools and parts are damaged.

Tool life management is built into a machine’s control, and the machine senses torque thrust and coolant. Chip condition is usually the first indicator of wear, which would otherwise require an operator present to detect, so the machine actually monitors the process and can predict tools starting to wear and identify when they need to be changed. A tool life management system also can count distances drilled and the number of cycles, then prompt a tool change at the appropriate time.

External robotic and conveyor part handling complements internal automation for effective, unattended deep-hole drilling.

That kind of in-machine automation smooths the path for external automation. As the process builds, highly standardized options for robot-ready machines such as an automatic door, workpiece-present sensors and programmable workpiece fixturing makes it easier to add a robot at a later date. These robot-ready machines also create efficiencies before they’re fully automated. Even with manual loading, the automatic doors and programmable clamping make the process more efficient.

In Unisig’s experience, an embedded reamer tool changer enables manufacturers to manage significant throughput increases, even with an operator. With this technology, operators can maintain the pace of production loading the machine, while eliminating the task of inserting reaming tools for each cycle. This allows the operator to redirect efforts towards tasks such as additional quality checks and off-machine setups.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreRead Next

Multitasking Machining Centers Double Throughput, Cut Costs

Purchasing one, then two more, multitasking machining centers has transformed the way Concours Mold Inc. builds molds.

Read MoreDrilling Machine Handles Large Workpieces as Long as 65 Feet

Unisig’s B850 drilling machine, part of the company’s B-series line designed for on-center drilling of round workpieces, features technologies designed to improve performance while reducing cost.

Read MoreTooling up for Deep-Hole Machining

Imparting complex geometry on the inside (and the outside) of workpieces requires the right equipment, the right cutting tools and the expertise to make the most of both.

Read More

.jpg;maxWidth=970;quality=90)