Share

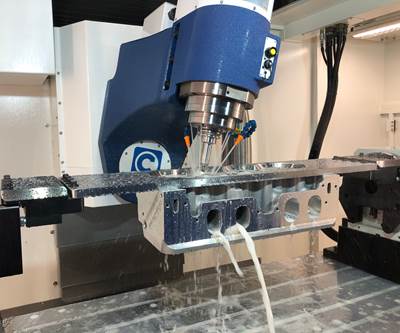

According to Sunnen, honing is typically required to achieve bore diameter tolerances of ±0.0002 inch or tighter with high quality surface finishes. (All photos: Sunnen)

As one of the most common machining operations, holemaking presents manufacturers with plenty of options. Depending on bore diameter and surface finish tolerance, a shop might choose drilling, milling, electrical discharge machining (EDM) or a combination of those CNC machining processes and achieve quality results. For example, the hole created by a 0.5-inch drill might range from ±0.002 inch or be as much as 0.006-inch oversized, but a subsequent reaming operation can produce a smoother surface finish and a hole diameter within ±0.0002 inch. Reaming or boring milled holes can achieve similar results, while EDM is even more precise, producing a bore diameter within ±0.0005 inch.

However, there are good reasons to turn to honing for applications with the most stringent requirements for surface finish and precision. According to Sunnen, a manufacturer of honing equipment that provided the information for this article, EDMed holes typically require further processing to smooth surfaces. The process is relatively slow as well. Optimized milling processes followed by boring or reaming may produce high-quality results, but not always consistently. Honing achieves all three goals: That is, the process consistently and reliably achieves bore diameter tolerances of ±0.0002 inch or tighter with high-quality surface finishes.

Honing is a sizing and finishing operation in which a revolving tool (mandrel), fitted with abrasives, strokes in and out of a bore. During the process, the abrasives are expanded, removing minute amounts of material to bring the hole to its proper size and finish. The resulting finish consists of microscopic peaks and valleys arranged in a crisscross or “crosshatch” pattern. The valleys allow oil retention between mating components during operation, such as pistons within an engine cylinder.

Although the process has been performed for many years, honing technology has evolved, and some manufacturers still have questions about it. Here are five of the most common:

1. What applications commonly call for honing?

Engine cylinders and cylinder sleeves require honing for proper piston ring sealing. Diesel engine fuel system components are often honed because honing enables tighter control of the clearance between the bore and its mating part. The resulting higher fuel system pressure means more fuel is atomized and less unspent fuel is used, resulting in improved fuel efficiency and engine performance as well as lower carbon emissions.

Tooling for honing is selected based on application requirements.

Cartridge valves, used in hydraulic applications such as heavy equipment, agricultural machinery, and aerospace flight and landing gear control systems, are typically honed. This provides tight clearances between the valve body and spool to reduce the sealing area required. Honing also creates the proper surface finish for the oil seals, which, combined with reduced clearances, prevents oil leaks.

Honing also improves the bore diameter size and surface finish of gun barrels prior to the rifling operation. This ensures uniform rifling for a better shot. The process is also useful for gears, small engines, brake drums, compressors, oil and gas flow meter tubing, and many other applications.

2. What unfavorable bore conditions can honing remedy?

Quite a number, including bore diameter size, bellmouth, waviness, taper, rainbow, barrel shape, reamer chatter, boring marks and out-of-round holes. The improved shape of the bore after honing almost always results in mating components operating more quietly and efficiently. Honing can correct errors caused by previous machining processes because it does not require chucking or alignment and is indifferent to bore length.

Honing can correct errors caused by previous machining processes.

Other machining processes, such as grinding and boring, might fracture the metal’s subsurface to a depth of 0.002 inch. In addition, tool wear can cause work-hardening of the bore surface during machining. Honing is a gentler process, generating very little heat so as not to distort the bore.

3. What types of surface finishes can honing achieve?

Surface finish, texture and appearance can be precisely controlled. The angle of the crosshatch pattern can be adjusted by varying the spindle speed and stroke speed of the honing tool. Some applications call for a steep crosshatch angle in the bore, while others require a shallow angle. The depth or roughness of the crosshatch pattern depends on the relative size of the abrasive grit in the honing stone. The larger the grit, the rougher the finish. A mirror finish with almost imperceptible surface texture can be achieved with very fine grit abrasives.

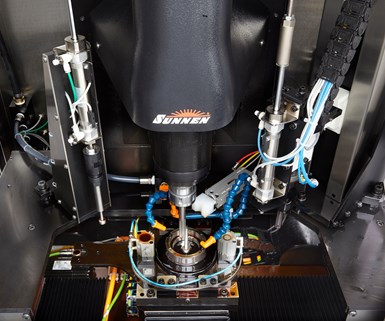

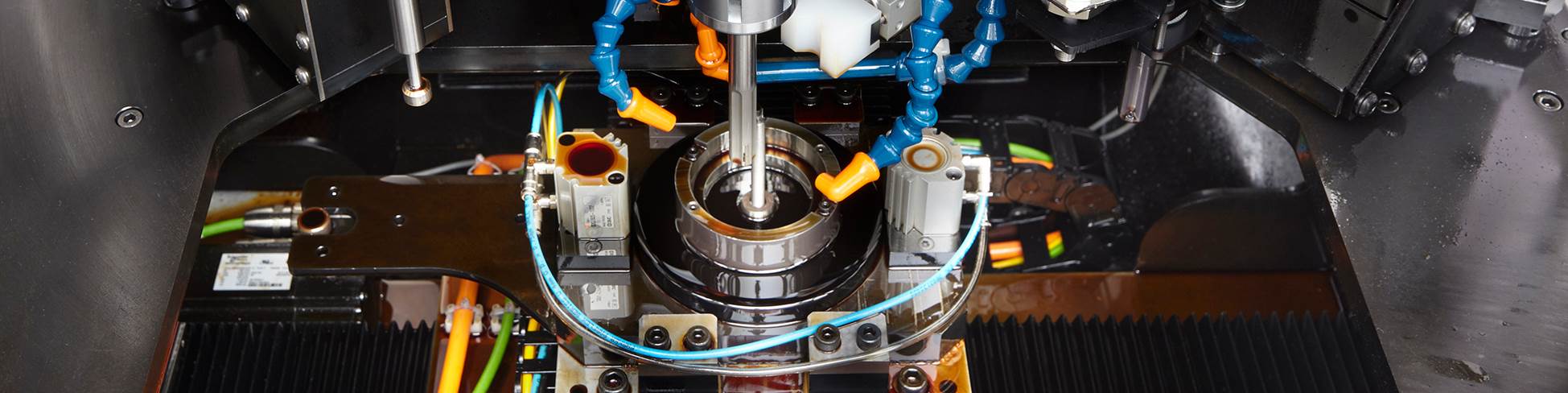

Like other machining operations, honing lends itself to robotic automation for high-volume applications.

As mentioned earlier, the crosshatch pattern created during honing is beneficial for applications such as engine cylinder bores to ensure some oil is retained on the bore surface for proper piston ring lubrication and piston ring sealing. Oil will not adhere well to a smooth or glazed cylinder bore surface, leading to premature wear and possible engine failure. If desired, a second honing operation using specialized tools can follow initial honing to create a plateau finish in which the peaks are uniformly clipped at a consistent level while leaving the valleys untouched. Most engine cylinders today are honed with this plateau surface finish, which increases the bearing area of the bore surface. This means conventional piston ring “break-in” processes are not required and the microscopic peaks that are honed off before the engine is assembled do not end up in the engine oil upon startup.

4. What is involved in establishing an effective, consistent honing process?

Like CNC machining, a number of questions must be answered when developing an optimized honing process. What is the part material, size and shape? What is the production volume? How much material needs to be removed? What are the finished workpiece bore tolerances and surface finish requirements? Answers to those and other questions determine the proper machine, fixtures, tooling, abrasives and honing oils or coolants, as well as honing process parameters such as spindle and stroking speeds and feed rate. The honing stone is selected based upon the type of material to be honed, tolerances to be achieved and the amount of material to be removed. There are as many types of abrasive honing stones available as there are types of milling or turning cutters, differentiated by grit material, grit size and bonding agent.

Honing oils are available in many different formulations and have various levels of viscosity.

5. How does lubrication affect honing?

Honing oils and water-based coolants provide needed lubrication, washing away cut material and bringing new abrasive grit to the surface of the stones to maintain optimum cutting action. Quality oils, saturated with surface active agents, provide the necessary lubricity to increase honing pressure and use harder abrasives at faster cutting rates. Similarly, lubricity agents combined with sulfur extreme-pressure additives prevent workpiece welding and tearing while keeping stones clean, resulting in a very consistent surface finish. Specially formulated honing fluids are also are available for use in severe applications in which problems such as galling can occur. Honing oils are available in many different formulations with various levels of viscosity. Environmentally friendly oils that are 100% vegetable based.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreRead Next

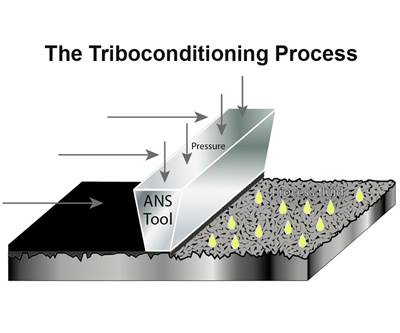

Sunnen and ANS Collaborate on Friction and Wear Reduction Technology

Triboconditioning is a combined mechano-chemical surface treatment process which uses a machining procedure to level off surface peaks and apply a friction- and wear-reducing compound to the component surface.

Read MoreSetting a Roughness Goal and Meeting It

Subjective surface finishes have no place in today’s high-precision manufacturing environment.

Read MoreCNC Machining and Motorsports

Have a look at some of the new manufacturing equipment spotted in “Machinery Row” at the recent Performance Racing Industry Show.

Read More

.jpg;maxWidth=300;quality=90)