In the Groove for 50 Years

It’s an American success story. In 1964, William and Hazel Kaiser founded a company to produce and market Thinbit, an innovative line of grooving tools. At first, the business operated out of the couple’s attic and garage. Fifty years later, the Kaiser Tool Company’s products continue to help shops such as Mack Tool and Engineering with successful solutions for demanding grooving applications.

Read MoreMetal Storm Thunders through Sudbury

Methods Machine Tools Inc. hosted its annual open house and mini machine tool show at the company's headquarters in Sudbury, Massachusetts, last week. The highlights of this customer event are here.

Read MoreDeep Holes with a Difference

Upgrading its deep-hole drilling capability with a Precihole three-axis machine from Absolute Machine Tools made a positive difference in this shop’s part processing, business strategy and customer service.

Read MoreMachine Monitoring Proves Its Worth

These three short case histories document the value of implementing a manufacturing execution system for machine monitoring. In each case, MERLIN hardware and software modules from Memex Automation led to productivity gains and improved overall equipment effectiveness (OEE).

Read MoreEmpowering the American Supply Chain

Major U.S. industries such as automotive will face shortages of parts and the production tooling to make them unless American suppliers step up to increase capacity. An expert in online marketplaces suggests strategies that will bolster the supply chain in this country.

Read MoreGood Enough Rarely Is

When it comes to acquiring a new machine tool, buying one that is just “good enough” may be short-sighted and disappointing.

Read MoreDynamic Motion Moves Past Old Boundaries

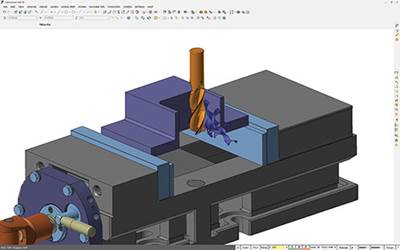

The Dynamic Motion option in CNC Software’s Mastercam generates tool paths by following an expansive set of rules that are different from those most CAM software has traditionally followed. The motion of the tool is not defined strictly by boundaries of the area to be machined. Instead, the rules take into consideration not only the area from which metal is to be removed, but also the changing condition of the material throughout the various stages of machining.

Read MoreQFS Keeps Its Customers Moving With Integrated CAD/CAM

Quickly updating tool paths to remachine die surfaces enables this shop to provide short runs of prototype formed sheet metal parts. This fast response to engineering changes and design adjustments helps its customers adhere to tightly scheduled vehicle launch programs. QFS relies on integrated CAD and CAM software to make this happen. In this case, the software of choice are PowerShape and PowerMill from Delcam.

Read MoreBallbar Basics—Running around in Circles

A ballbar testing system has three main components: the ballbar, a precision magnetic mount that attaches to the machine table, and a second precision magnetic mount that attaches to the machine spindle or spindle housing.

Read MoreThese Coolant Videos Are Cool

Haas Automation has created a series of educational videos on proper coolant maintenance. The mix of animated graphics and how-to demos is just right (just like the mix of coolant concentrate and water should be).

WatchSurprises from Machine Monitoring

When Mazak implemented an MTConnect-enabled machine monitoring system at its machine-tool factory in Florence, Kentucky, the data yielded some surprising results when analyzed. Read about what was discovered here.

Read MoreJob Shop in Sweden Installs Haas’s 150,000th Machine

The milestone machine—a dual-spindle turning center with a Y axis—was installed in a job shop halfway between Stockholm and Gothenburg.

Read More