MMS Blog

Pick the Right Stock to Avoid a Bad Quote

Stock selection can have a big impact on a machine shop’s bottom line. When quoting a job, don’t fall into the trap of minimal material mentality.

Read MorePeople-First Mindsets Improve Machine Shop Acquisitions

Focusing on the human side of the business — employee health, safety, success and growth — is the only way to satisfy both the buyer and seller.

Read MoreHow to Match Thickness Gage Types to Proper Applications

Different thicknesses require different gage types during inspection — four common ones are handheld indicators, handheld micrometers, opposed air streams and gage blocks.

Read MoreWebinar | Automated CNC Machine Setup for the Smart Factory

Learn how to maximize the value of your CNC equipment through automated setup with Jon Caliguri of DSI.

Read MoreManufacturing E-Commerce Expands with Expectations

Whether by automating on their own terms or joining a vetted network, manufacturers are responding to demand for easy online part ordering.

Read MoreNew Grinding Machine Utilizes Unique Kinematics

A novel grinding machine uses three rotary tables stacked off-center to provide full control over the grinding wheel’s X and Z axis, as well as its angular position, creating an unusual solution to grinding.

WatchChoose the Correct ID/OD Gage for the Task

Benchtop and portable comparator gages each have their place, but the differences are more than surface deep.

Read MoreHolding Submicron Part Tolerances

Sunlight-Tech Inc. has used GF Machining Solutions’ Microlution laser micromachining and micro-milling centers to produce parts with tolerances tighter than 1 micron.

Read MoreNidec Acquiring Mitsubishi Heavy Industries Machine Tool

Motor manufacturer looking for ways to more efficiently manufacture so it is buying a machine tool company

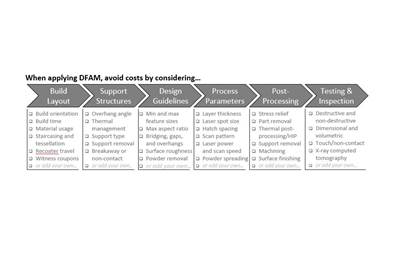

Read MoreAvoiding Costs while Adding Value with DFAM

Design for Additive Manufacturing (DFAM) is as much about finding value as it is about avoiding costs with AM.

Read MoreMachine Tool Orders Boom in December 2020

Machine tool orders reached their highest level since September 2018 (the last in-person IMTS) and their highest level outside of an IMTS month in three years.

Read MoreMoving Monitoring Closer to the Cut

A sensory toolholder can provide more accurate vibration data on the metalcutting process, helping to extend tool life and improve surface finish.

Read More