-

SPONSORED

-

SPONSORED

-

SPONSORED

MMS Blog

Turning Ideas Into Parts

To get maximum leverage from its manufacturing know-how, Krieger Machine, a CNC shop in Stuart, Florida, draws on all of its software resources - CAD, CAM and shopfloor programming. The shop relies on KeyCreator from Kubotek as its main CAD resource. Mastercam from CNC Software is its main CAM resource. On the shop floor, conversational programming on the Hurco vertical machining centers proves to be another vital resource. All three systems help the shop succeed as a reliable producer of precision parts for a variety of industries.

Read MoreItalian Offerings In Unattended Machining

From BI-MU 2004, here are a few examples of Italian companies addressing the need for unattended production and single-setup machining.

Read MoreJIMTOF Puts Nanotechnology Under Magnification

The big theme at the Japan International Machine Tool Fair (JIMTOF) was nanotechnology—the ability to produce parts to submicron accuracy.

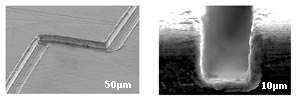

Read MoreMachining Under The Microscope

Sandia National Laboratories experiments with turning and milling tools just 10 and 20 microns in size.

Read MoreEnd Mill Designed For Ramping

Features of the tool facilitate ramping and other aspects of milling holes and pockets.

Read MoreService Phone Saves Productive Time

One machine supplier adds a cell phone to the CNC as a way to provide immediate access to service support.

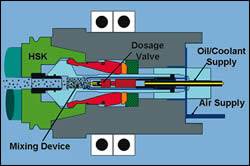

Read MoreUnderstanding MQL

Minimum quantity lubricant can save money, improve tool life and improve the part finish. But it may involve changes to both the equipment and the processing strategy.

Read MoreGetting To Submicron Accuracy

Machie tools designed for submicron accuracy and subminiature workpieces are following design strategies that depart from conventional practice. The Hyper2J from Makino is described as a case in point.

Read MoreDeveloping A Safer Way To Machine Magnesium

Machining magnesium is risky business, as the chips and dust generated are flammable. A research consortium has developed a novel way to extract magnesium particles out of the machine by vacuuming them through a hollow tool and spindle during machining.

Read MoreMachining More Than Meets The Eye

Manufacturing parts that may be smaller than the chips generated during machining requires more than just the right cutting tool and machine. It requires a micro-mindset that focuses on all aspects of tiny parts processing--handling, inspection, finishing and assembly.

Read MoreVertical Machining Centers For Volume Production

At this model plant for lean manufacturing, Parker Hannifin personnel became convinced that the simple approach was the strongest choice for the application. Part of the lesson learned at this plant is that the most difficult part of going lean may lie in the discussion.

Read More