Turning Ideas Into Parts

To get maximum leverage from its manufacturing know-how, Krieger Machine, a CNC shop in Stuart, Florida, draws on all of its software resources - CAD, CAM and shopfloor programming. The shop relies on KeyCreator from Kubotek as its main CAD resource. Mastercam from CNC Software is its main CAM resource. On the shop floor, conversational programming on the Hurco vertical machining centers proves to be another vital resource. All three systems help the shop succeed as a reliable producer of precision parts for a variety of industries.

Share

"Shut up and make the part."

These are words that Aaron Krieger uses to describe the attitude of many customers when he started Krieger Machine Company 24 years ago in Stuart, Florida. There wasn't much dialog with design engineers. In those days, customers simply expected a job shop to make parts to print. Of course, part prints and spec sheets were all Mr. Krieger needed to put his manual equipment to work.

Today, the shop relies on CNC milling machines and machining centers to make customers' parts, but capable machines are not the only big attraction, according to Mr. Krieger. "We can start making parts no matter where a design engineer may be in the design process," he explains. That flexibility and responsiveness is what customers look for these days, he says. "They want us to be problem solvers."

That means being able to interact effectively with design engineers, whatever form or format the information about a part is in. Sometimes the information arrives as a fully developed solid model created in a CAD system such as CATIA, Pro E or SolidWorks. In other cases, traditional paper prints are the only source of information about a part that was designed long before data could be captured digitally. Sometimes the parts are merely ideas in the developer's head.

"We have to respond to hand signals like this," says Mr. Krieger, tracing a rectangle in space with his index fingers. "They want us to make a part that is so wide and so tall, with drilled holes here and there," he says, poking the air.

To be this flexible, Mr. Krieger finds that a variety of software resources are needed. The shop has a CAD system to manipulate or create part geometry in a digital format. It also has an offline CAM system for generating G-code part programs. Finally, the CNC milling machines and machining centers have control systems offering shopfloor conversational programming directly at the machine. These dual-screen control systems also let the shop import geometry generated on a CAD system and run the part programs generated on the CAM system.

Evolution

KMC's flexible, integrated approach evolved naturally out of the shop's first experiences with CNC. For the first 6 or 7 years as a shop owner, Mr. Krieger relied on his skill as a trained machinist to handle incoming jobs. By the mid-1980s, however, he saw that moving into CNC was clearly the only way to survive.

Fortunately, he found an approach that allowed him to think like a machinist yet still successfully program a CNC machine. The answer was a conversational programming system that asked for information about the part in an intuitive, logical pattern. "I knew how the part had to be machined," Mr. Krieger says. "I could see that in my mind. The conversational programming let me get that picture onto the control screen, where it could become the CNC program for machining the part."

Confident that shopfloor programming could make CNC operations successful in his shop, Mr. Krieger acquired a KM3-P milling machine from Hurco (Indianapolis, Indiana) in 1988. This machine came with the Ultimax II conversational programming system, which featured a dual-screen format. One screen displays the choices and machining options while the second side-by-side screen displays the part geometry and tool path as defined in response to prompted selections.

This machine was successful. A second machine, almost identical to the first, was installed 1 year later. Three more machines were installed in the last 5 years. All three are Hurco BMC 4020 machining centers with Ultimax III or IV controls. Fully established as a CNC shop, KMC has prospered, with a growing reputation as a reliable producer of preliminary prototype/development units, initial low rate or long-term high quantity production jobs for the electronics, jet engine and medical imaging industries.

Software Resources

Adding CAD and CAM has helped KMC maintain this momentum.

KMC's main CAD resource is a seat of KeyCreator from Kubotek USA (Marlborough, Massachusetts). This CAD software is an enhanced version of the PC-based CAD system formerly called Cadkey. This CAD system came to KMC when Mr. Krieger brought John Goings on board last year to help him manage the shop. Mr. Goings knew KMC well from his experience as a business unit manager at one of the shop's longtime customers. Mr. Goings also had a strong background in manufacturing and CAD applications. His knowledge of CAD was especially useful.

CAD software allows the shop to work with geometry in almost any format, including 2D or 3D wireframes, surfaces or solid models—the prevalent format for conveying part geometry today. When a customer's part geometry is sent to KMC (usually by e-mail), Mr. Goings opens the file in KeyCreator and translates it into the system's native format. At this point, he and Mr. Krieger analyze the geometry and determine a basic manufacturing strategy. This strategy is the basis for quoting the job.

Any gaps or errors in the geometry are patched at this time, making it usable for machining applications. Likewise, the dimensioning and drafting features of the CAD software make it easy to create 2D drawings for the shop floor at this point.

KMC's main CAM resource is a seat of Mastercam from CNC Software (Tolland, Connecticut). Mr. Krieger acquired this software in 2002, mainly because it provided programming support for workpieces with splines, NURBS surfaces and other complex geometry. In addition, he saw the need for an off-line CAM system to move some of the three-axis programming burden away from the machine tools. Because the control systems on the CNC machines accept G-code part files, this CAM software gave the shop more flexibility in distributing programming activities.

Most CAM programming starts with customer-furnished geometry imported as a STEP, Parasolids, ACIS or IGES file. Importing the data avoids reconstructing the geometry or risking data entry errors. This streamlines the process of generating tool paths. The resulting G-code files are transported to the machines by diskette or network cable.

Although CAD and CAM are valuable and necessary, Mr. Krieger still considers the capability of the machine tool control units and the shopfloor programming to be the cornerstones of his shop's machining flexibility. "The conversational mode is the quickest way for our shop to get a part into the cut," he says. Working with the occasional customer who wants a prototype produced from "hand signals" is an example of the instant programming this option provides.

More importantly, shopfloor programming has advantages on a daily basis. "It gives us the most flexibility for editing, modifying and optimizing the part program," Mr. Krieger says. Engineering changes from the customer can be accommodated easily, he says. A "data block search" feature helps locate the exact spot where new data values have to be entered, for example. With shopfloor programming, there is no need to return to the CAM system, edit the program and reapply the postprocessor. There is no need to carefully manage multiple versions of a part program: The latest version is always the one saved in the memory of the control unit at the machine. Programs created conversationally also tend to be much shorter in length compared to comparable G-code programs, which makes them easier to archive and transport.

Finally, Mr. Krieger reports that his shop rarely has to make test cuts because the precision of the tool paths prepared conversationally and the accuracy of the machining centers have proven to be very reliable.

Synergy

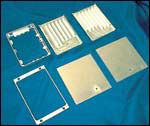

Synergy between CAD, CAM and shopfloor programming recently helped KMC land a job with a new customer. The part was an aluminum enclosure, roughly the size of a small cigar box, that housed printed circuit boards that control an electronics system for aircraft. A frame around the four outer sides allowed the enclosure to be mounted directly to an instrument panel. The interior of the enclosure featured numerous slots and drilled mounts for installing the circuit board racks and attaching the front cover/operator panel.

"To bid on the job, we were given a sample part and a set of part prints," Mr. Krieger recalls. "When John and I inspected all the geometry inside the enclosure, we knew this would be a challenging project."

Mr. Goings created a solid model of the entire enclosure in KeyCreator from customer-supplied drawings. The solid model allowed the two men to rotate and view the geometry from various angles so that they could conceptualize how it could be "cut up" into separate components that could be machined individually. They saw that using off-the-shelf extruded aluminum stock in standard sizes could reduce waste and minimize material costs. These components could then be assembled into a complete piece. Mr. Krieger suggested that the assembled pieces could be tack-welded together, then aluminum dip-brazed off site.

Based on this preliminary manufacturing strategy, KMC submitted a bid. The very competitive pricing of this bid solicited strong interest from the customer, who was still a bit wary of signing on with a new and unfamiliar contractor.

"We decided that delivering a sample part of our own might clinch the deal," says Mr. Krieger. Mr. Krieger and Mr. Goings gave themselves 2 weeks to produce the sample, including 1-week turnaround time for the aluminum dip-brazing. That meant machining all of the components in about 4 days while maintaining current production in the shop.

Working from the part model in CAD, Mr. Goings created separate files for each machining setup. For example, the exterior of each side panel was one setup; the interior (flip side) of each panel was another setup. Mr. Krieger earmarked the simpler exterior machining for shopfloor programming, while he relegated the more complex and repetitive geometry of the interior to the CAM system. Mr. Krieger took on the shopfloor programming duties and assigned the CAM programming to Shuford Swift, KMC's main Mastercam programmer.

"At the Hurco, I imported the geometry as DFX files on one screen and began following the prompts to build the tool path conversationally," Mr. Krieger explains. "This allowed me to selectively choose the portions of the geometry called for by the prompts without having to reconstruct it line by line, arc segment by arc segment." A similar time savings was achieved at the CAM station by importing the appropriate geometry.

Because of the flexibility of the machining centers' control units, the first operation was created conversationally on one machine, while the second operation was programmed in Mastercam and run in G code at another machine. "This gave us ideas for multiple setups for the production run if we won the job," Mr. Krieger says. The shopfloor programming system allows KMC to easily create patterns for repeating or alternating programs to match multiple part setups. "This is huge," Mr. Krieger says. "It makes the transition from prototyping to production much smoother and faster."

When all of the separate components had been machined, interlocking edges allowed the four sides to mate with the bezel while the outer frame was slipped over the other end. This design formed a freestanding shell with all details finish-machined inside and out, all set for tack-welding.

"When we presented the sample to the customer, it made a very positive impression," Mr. Goings says with satisfaction. "We won the order."

Making Know-How Count

For Mr. Krieger, being able to share manufacturing know-how rather than merely selling machine time makes life as a job shop owner more rewarding. Interacting with design engineers and responding effectively is a more satisfying use of skill and experience than it was in the "shut-up-and-make-the-part" days. The key is having the machining and the software resources to turn ideas into parts. That makes all the difference in the value a shop can add, especially when creativity counts as much as productivity.

Related Content

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)