MMS Blog

“Spirograph” Generates Face Grooves on a Machining Center

Sandvik Coromant's unusual "SpiroGrooving" system uses an adjustable toolholder to machine API grooves on a machining center.

Read MoreSophisticated Software for Solid Gear Design

Whether your computer platform is standalone or part of a suite, desktop or on the cloud, there’s a gear design package developed specifically to meet your needs.

Read MoreAlternate Coolant Delivery Method Made a Difference

Haimer's Cool Flash toolholder delivers coolant through small slits to cover the entire tool circumference.

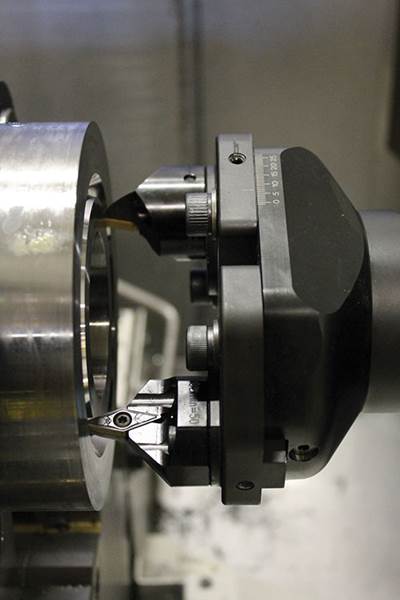

Read MoreThe Cutter Affects Capacity

New machine tools allowed CTG to cut cycle time by 75 percent, but that wasn’t enough. Finding the right tool and process cut that cycle time further, giving the oil-industry manufacturer the capacity needed to support an important new product.

Read MoreA Map for Market Expansion

How one gear manufacturer freed itself from the single-customer model by adopting new technologies and expanding its customer base to protect against economic uncertainties.

Read More7 Things to Know about the IIoT and Industry 4.0

An introduction to the standards, decision-making, training, cybersecurity, sensors, machine monitoring and cloud computing that make up the IIoT.

Read MoreDimension-Over-Ball Gage Measures Spurs, Helical Gears, Splines

United Tool Supply’s Unite-A-Matic gage checks dimension over ball (DOB), dimension over pin (DOP), and major/minor diameter of spurs, helical gears and splines.

Read MoreImportant MTConnect Deadlines Announced

Students have a new date to submit ideas for applications using the MTConnect interoperability standard as part of the MTConnect Student Challenge. It’s now December 15, 2015. Speakers interested in presenting at next year’s [MC]2 Conference on MTConnect in Dallas should submit proposals by October 16, 2015, for the first round of consideration. The conference dates are April 19-21, 2016.

Read MoreSeven World Premieres Highlighted at Innovation Days in Japan

During DMG MORI's “Innovation Days” event in Japan, the company showcased 58 machine tools in its newly renovated Iga Global Solution Center, which boasts 3,500 m2 (37,674 ft.2) of floor space.

Read MoreGrowth in Robotics Good for U.S. Manufacturing

In order to get a good grasp on the current state of manufacturing in the United States, it’s important to monitor the health of related markets such as robotics.

Read MoreThe Machinist Garden

The lettuce is growing great. But can this team of precision machining specialists get watermelon to grow in Connecticut?

Read MoreWhat’s It Like to Work in a Machine Shop Underground?

A machine shop housed a mile below the surface is a very unusual workplace, especially when it has to operate in a cleanroom environment. It’s the only way to make parts that are not affected by cosmic rays. Conditions in another shop underground are rather normal, but being in a cave has advantages for this shop, too.

Read More