“Spirograph” Generates Face Grooves on a Machining Center

Sandvik Coromant's unusual "SpiroGrooving" system uses an adjustable toolholder to machine API grooves on a machining center.

Share

Using a lathe to machine a groove into the face of a turned part requires different toolholders for different groove diameters. That fact is second nature to many shops, but it is a curiosity to shops that don’t do this grooving. The reason different groove diameters need different tooling becomes obvious upon seeing the operation: The blade of the toolholder has to descend with the cutting insert into the groove as it is machined. Since the blade has to fit without touching either the inner or outer wall of the groove, it needs a curvature to match. This is why machining grooves through face turning presents the problem of additional tooling inventory for every different increment of groove size. And arguably, that is the least of the challenges with this operation.

Face grooves are also often a feature on parts that are poorly suited to turning. An example is oil-industry valve bodies, which might have different flanges that get these grooves facing out from one another at right angles. Indeed, another challenge in the oil industry is the specifications of the grooves. The American Petroleum Institute (API), aiming for a tight fit with the seal ring in this groove, requires the groove to hold a tolerance of ±15 minutes on its 23-degree-angled walls and finishes of 32 and 63 microinches RMS on its surfaces. These specs are difficult to hold when plunging a turning tool into the material results in a high-wear operation apt to quickly compromise the cutting edge.

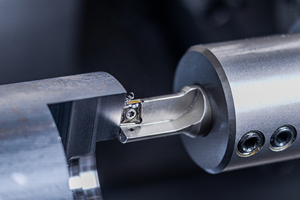

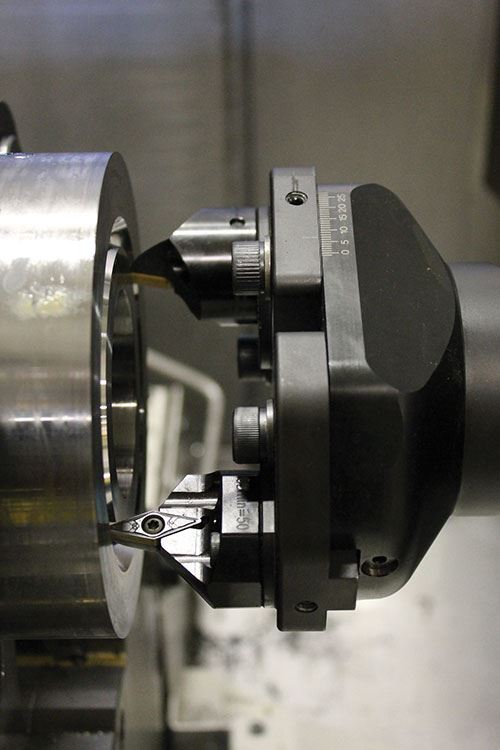

Cutting tool maker Sandvik Coromant has been focused on those very specs in its efforts to develop a more manageable and reliable system for seal-ring groove machining. The unusual solution the company has developed does not use turning at all—or at least not turning on a lathe. Instead, Sandvik’s new “SpiroGrooving” system uses an adjustable toolholder to machine API grooves on a machining center. Two turning and boring inserts are simultaneously rotated and helically interpolated to generate the groove.

The toolholder is an adjustable device that positions the two V-style inserts at a distance appropriate to the groove diameter. Users manually adjust the holder and tighten bolts to clamp it at this diameter. And because of the helical interpolation, this hardware is matched in importance by a software utility that is also part of this system. The user inputs the groove diameter along with the desired cutting pitch and chip thickness (both dependent on workpiece material) to allow this utility to generate the NC code for the tool path particular to this API groove.

The tool path is not a simple helix. As the spindle spins the custom toolholder in time

with the helical orbit inside the groove, each of the two inserts alternates between cutting the inner and outer wall of the groove. The diameter of the helical path then tapers as the cut advances so that the cutting action of the inserts follows the 23-degree slope of the wall. This rotation within a tapering spiral produces a complex resultant tool path that Sandvik describes as an “intelligent spirograph.”

The path is hard to picture—video helps. Watch slow-motion video of the SpiroGrooving tool cutting an API groove.

That video also makes clear how neither of the cutting inserts is overloaded. Each insert moves in and out of the cut throughout its progression through the spirographic path, and each insert alternates between cutting on each of its available edges. The system can therefore cut the groove at a rapid penetration rate without the tool wear that might compromise the groove’s tolerances. As a result, this system is potentially a means of not only simplifying API grooving and moving the operation to a machining center, but also simply cutting the groove more quickly.

Related Content

Rego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreThrough-Coolant System Cuts Nickel-Alloy Cycle Times by 70%

Decker Machine Works recently adopted Rego-Fix’s reCool through-coolant system for ER collets, reducing the cycle times on a nickel alloy job by 70%.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)