A Map for Market Expansion

How one gear manufacturer freed itself from the single-customer model by adopting new technologies and expanding its customer base to protect against economic uncertainties.

Share

Takumi USA

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

There is a certain level of security to be found in the captive machine shop business model. You’re dealing with a single customer, whom you get to know very well, and there is a reasonable expectation of ongoing work. There is uncertainty as well, since market downturns can have a devastating impact with no alternate revenue streams to rely on. Market diversification is the obvious solution, but how does a captive gear manufacturer go about expanding its customer base and transforming itself into a contract shop?

The first step is to evaluate your strengths in terms of capabilities. What is the full range of gears you can produce with your current equipment lineup, and is there new business you can pursue based on those capabilities? When considering the products you’re manufacturing for a single customer, are there related markets you can enter with minimal capital investment? If you were to invest in new equipment, how many markets would it launch you into, and what would such an outlay cost? Are there any processes being outsourced that you could bring in-house to build your core competencies? Be sure you understand the latest machining processes and technologies, how they’ve evolved over time, and which would enable you to reach your goal.

By taking these steps, a machine shop can limit worries over market fluctuations, since a diversified customer base provides protection against market volatility. Here’s a look at how Global Gear & Machining achieved just such a transformation, adding 11 new customers to its base by taking a close look at its in-house capabilities and offering a range of machining resources to new markets.

Core Competencies

Based in Downers Grove, Illinois, Global Gear was established in 1991 as a captive supplier to Navistar. When the manufacturer of engine timing gears joined the IMS Companies in 2002, the decision was made to look into what it would take to expand the company’s capabilities in order to enter new markets. Having spent nearly two decades as operations manager for a successful and highly diversified contract supplier to the automotive industry, making everything from fuel injection components for gas and diesel engines to rocker arms and lifters, Cory Ooyen was brought onboard in 2006 to assemble a team to oversee Global Gear’s transformation. What he found was a company with a solid foundation and a reputation for quality that could be used as leverage in attracting new business.

Market diversification was one of his primary concerns in the new position. Looking closely at the company’s order history, he noticed a disturbing trend. Faced with changing emissions standards, engine builders had started over-ordering parts during the last six months of a fiscal year before new standards went into effect, stockpiling engines they would then draw from for months at a time. This left companies like Global Gear far too busy at the end of the year, and with too little work at the beginning of the next year, when its customer stopped placing orders while using up its supply of surplus engines. This “feast or famine” approach isn’t an effective business plan, so it was time for a change. But the company’s strategic direction first had to

be identified.

For the parts it was making, Global Gear relied completely on hobbing and shaving, primarily using Mitsubishi machines. It had a full complement of turning machines from Okuma, Mazak and Hyundai alongside machining centers from Mori Seiki and Brother. Any gear grinding work was subcontracted out. Bringing this process in house was a natural starting point to increase its capabilities by embracing the latest technologies.

Mr. Ooyen and his team began a careful examination of the top grinding machine OEMs, looking at equipment specifications as well as the level of customer service, technical support and on-site training each would provide. In the end, Liebherr was named the vendor of choice, and Global Gear purchased the first of two LCS 300 generating and profile grinding machines and recently added an LGG 180. It eventually invested in three hobbing machines from the same OEM—two LC 180s and an LC 300 that is on order—as well as three LSE 380 shaping machines. This bolstered the company’s range and capabilities in existing competencies such as hobbing and added new ones like gear shaping and gear tooth grinding.

A particularly valuable part of this exercise was having the opportunity to contrast and compare the current state of gear manufacturing technology. With new processes being introduced—think scudding, and power skiving—and more familiar methods constantly being improved, there was a consensus within the Global Gear team that grinding technology had in many ways outpaced other machining techniques in the gearing arena. More powerful machines, shorter cycle times and especially improved abrasives for maximum material removal were important, as was the excellent surface finish, reduced noise and vibration, efficient power transfer and tight tolerances that grinding provides. “In fact, we’ve gone from grinding zero gears in 2006 to about 70 percent ground gears today,” Mr. Ooyen says.

Still, other factors were considered, such as the fact that some machining processes simply can’t be performed on a grinder, like cutting internal teeth on gears of a certain size. Also, since Global Gear works directly from its customers’ plans, the required tolerances plus the AGMA class partially dictate what type of machining process should be used. The demand for tighter tolerances is the primary driver behind the recent growth in grinding technology.

After much research, the team decided on the following lineup of machining processes, in order to provide particular capabilities:

• Grinding is an abrasive process that uses a grinding wheel as the cutting tool. The process is used to perform finishing of high accuracy external or internal gear teeth after heat treatment.

• Shaping is a machining process that is commonly used to create teeth on a cylindrical part. It is very versatile in that it can be used to create either external or internal teeth.

• Hobbing is essentially a specialized milling process that is used to create external teeth for gears, sprockets and splines. It is the most common method for general gear manufacture.

• Shaving is a finishing process used to improve the accuracy of involute gear teeth after a process such as hobbing or shaping. It is normally performed prior to heat treatment.

• Turning is a machining process performed on a lathe to form the basic shape of a cylindrical gear blank. Turning is normally the initial operation performed on all gear products prior to cutting teeth.

With these processes in place, Global Gear had solidified its identity. Now it was time to identify new customers.

Expanded Capabilities

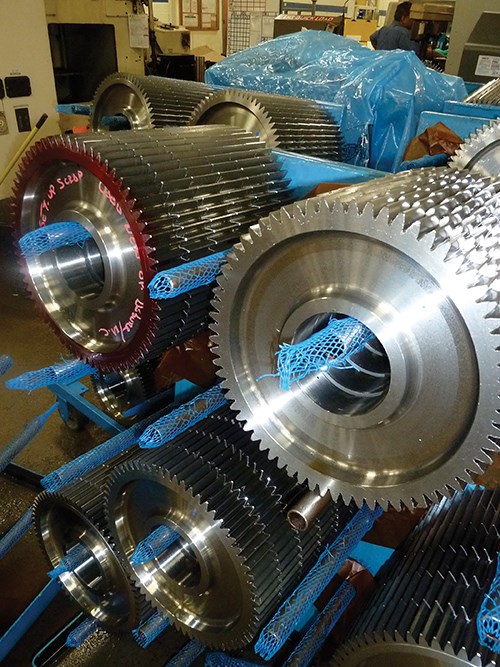

In its days as a captive gear shop, Global Gear specialized in making parts for class 4 and 5 medium-duty trucks, which still represent the majority of its work. Once it had invested in new technologies such as grinding, it was able to increase its range through the class 8 market, which includes commercial trucks with diesel engines with displacement volumes ranging from 3.9 to 15 liters. Not only did this make it possible to increase its offerings for truck engines, it opened up entirely new markets that the company had never been able to approach or service before, such as energy production and off-highway. Today, the company produces gears for engines up to 95 liters.

In his role as director of sales, Brad Rapciak was responsible for reaching out to potential customers. “I’ve been in the engine business for about 30 years,” he says, “so Cory and I relied on industry contacts to get our foot in the door.”

An open doorway didn’t automatically lead to new business, however. Typically, customers interested in testing the company’s capabilities would begin with small orders of aftermarket, or “service only” gears. They would first conduct an audit, send a team for a visit to the company’s 132,000-square-foot facility to observe process flows and equipment layout, slowly building order volumes over time.

The result of these efforts is that Global Gear has added 11 customers and entered seven new markets since 2010. From a captive shop with a limited customer base, the company now services the medium- to heavy-duty truck, agriculture, oil and gas, marine, power generation, mining and automotive markets. It ships its parts—including spur gears, shafts, helical gears, pulleys and couplings, and related precision machined components—throughout North America and Europe. Its gears range in size from 25 to 300 mm, widths to 150 mm, and modules up to 8.

Weathering the Storms

Global Gear is now seeing the results of its restructuring efforts. Thanks to its embrace of new technologies—particularly in grinding—the company is now involved in completely new business relationships. “We’re providing gears for automotive transfer cases because of grinding, and it also allowed us to get involved in the transmission gear business and to get into agriculture, which is a market we hadn’t been active in before,” Mr. Ooyen says.

Some of the payoffs are a little less tangible, however. By the very nature of its business model—or the one Global Gear followed, at least—a captive shop excels at making a few things exceptionally well for a single customer. Branching out awakens a company’s entrepreneurial drive. “Instead of focusing on one particular company, you get the opportunity to learn about other industries, to see how their operation works and start thinking creatively about how you can play a role in their success,” Mr. Rapciak says. “You get to learn about new manufacturing techniques, machining processes and applications you’ve never encountered before. It helps us build our knowledge base so that we can be more effective in working with all of our customers.”

In summing up lessons learned over the past nine years, the Global Gear team’s experience provides a good example to any manufacturing company interested in diversifying its market base, expanding its capabilities, and staying at the leading edge of current gear machining technologies:

• Take an inventory of your equipment to determine your capabilities.

• Decide whether or not they are adequate to meet your strategic goals.

• Take the time to learn about the current state of machining technologies.

• Make capital investments based on your findings and the parts you want to make.

• Seek out equipment suppliers that provide in-house training, technical expertise and service beyond the point of sale, and begin building relationships with them.

• Train your own staff—you can’t expect to easily find experienced operators anymore.

• Write a detailed business plan explaining your process, goals, machining capabilities and shipping strategies to share with potential customers, displaying a clear vision of your company and its strengths.

• Be sure that no one market or customer represents more than a certain percentage of your annual revenue.

The last point, in particular, is especially relevant. “I’ve seen companies that relied too heavily on one market, or one customer, and when the economy faltered, they ended up going out of business because they didn’t have a backup plan. You have to be able to ride out that storm,” Mr. Ooyen says. “It’s going to come, you just have to find a way to ride through it.”

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)