MMS Blog

Using Additive Manufacturing to 3D-Print Fixturing, Machine Tool Components

Machine shops can consider 3D printing technology a handy way to make custom fixturing and other components.

Read MoreInner-Diameter Part Clamping Offers Lathes Complete Outer-Diameter Access

Royal Products' CNC expanding mandrels provide access to the entire outer diameter of the workpiece.

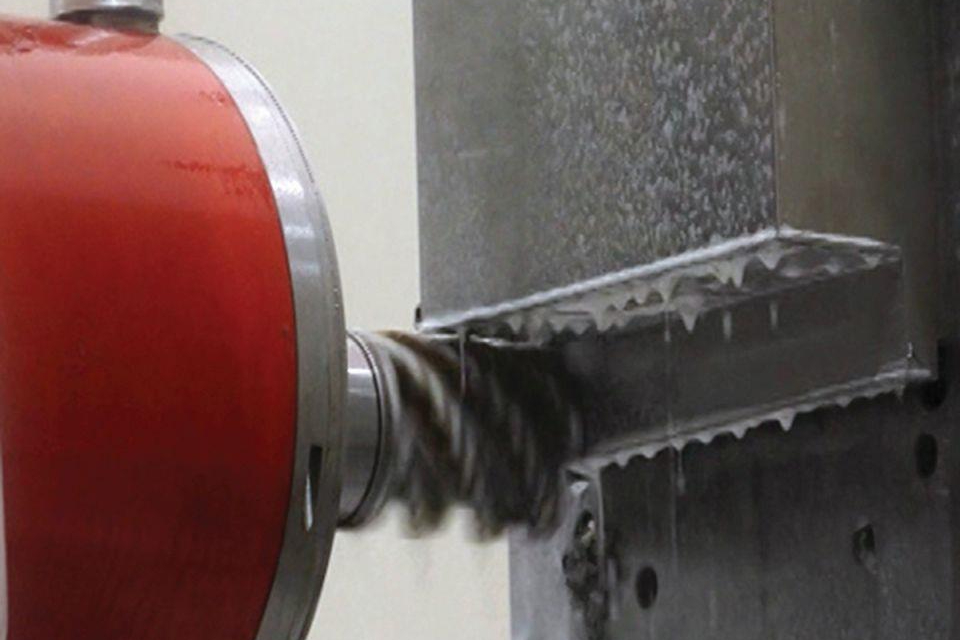

Read MoreOn Power, Torque, Speed and Hogging Titanium

The T-Rex spindle from Fives Giddings & Lewis is designed for high-torque and low-speed cutting critical for hogging titanium.

Read MoreInventory Systems Boost Lean Manufacturing Efforts

Computerized, point-of-use storage and dispensing systems help this shop target waste that is difficult to measure and often labor-intensive to eliminate.

Read MoreChances for Hybrid Manufacturing in Oilfield Applications

A contract manufacturer is finding uses for a hybrid additive manufacturing and five-axis milling machine for oilfield drills, valves and other end-use components.

Read MoreKeeping a Shop Network Safe

Concerns about cyber security should not stop shops from installing machine-monitoring systems.

Read MoreVideo: Multipurpose Tool Developed Using Various Operations

3D printing, waterjet, CNC machining and metal injection molding all figure into the journey this military-inspired invention has taken so far.

WatchTop Shops Profile: Tech Manufacturing

Tech Manufacturing was the 2016 Top Shops Honors Program winner in the category of shopfloor practices.

Read MoreU.S. Manufacturing Is Set for Stability and Growth

The Reshoring Initiative intends its infographic to help manufacturers as they plan for Manufacturing Day coming up on October 7.

Read MoreUsing Collaborative Robots for Laser Scanning

This device is said to be the first programmable laser scanning system for automated 3D scanning, measurement and gaging using a collaborative robot.

Read MoreVideo: Machine Shop in San Quentin Prison

The TV program “Titan” will become more directly focused on machining instruction as its creator incorporates his teaching in the prison into the show.

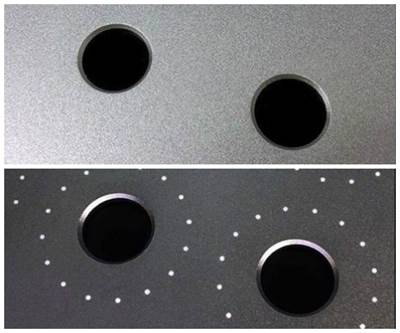

WatchDrilling “Invisible” Holes

UV laser micromachining makes it possible to drill holes that are not visible to the human eye—until they are meant to be seen, that is.

Read More