Drilling “Invisible” Holes

UV laser micromachining makes it possible to drill holes that are not visible to the human eye—until they are meant to be seen, that is.

Share

Hwacheon Machinery America, Inc.

Featured Content

View MoreHow do you drill a hole smaller than the diameter of a human hair? Baltimore, Maryland-based Potomac Laser turns to UV laser micromachining for such applications. This process directs a laser beam onto the surface of a material and the energy of the laser is converted to heat which vaporizes or melts the material. With this technology, the shop can rapidly drill very small holes spaced 50 microns or less apart in metals less than 0.003-inch thick.

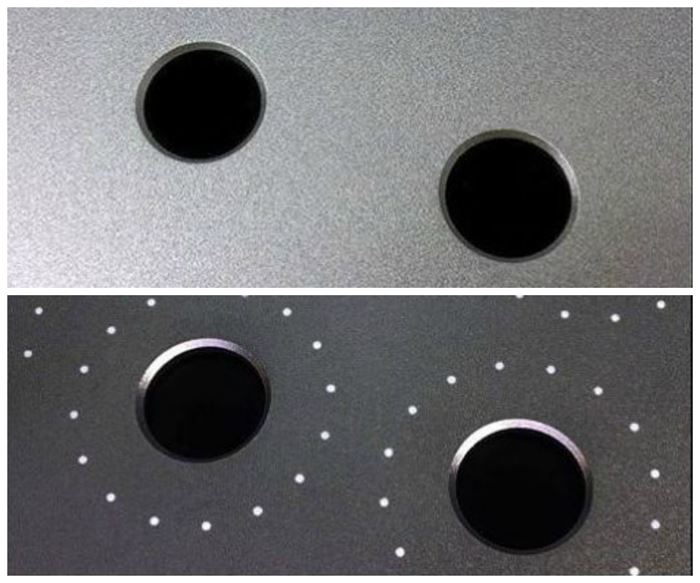

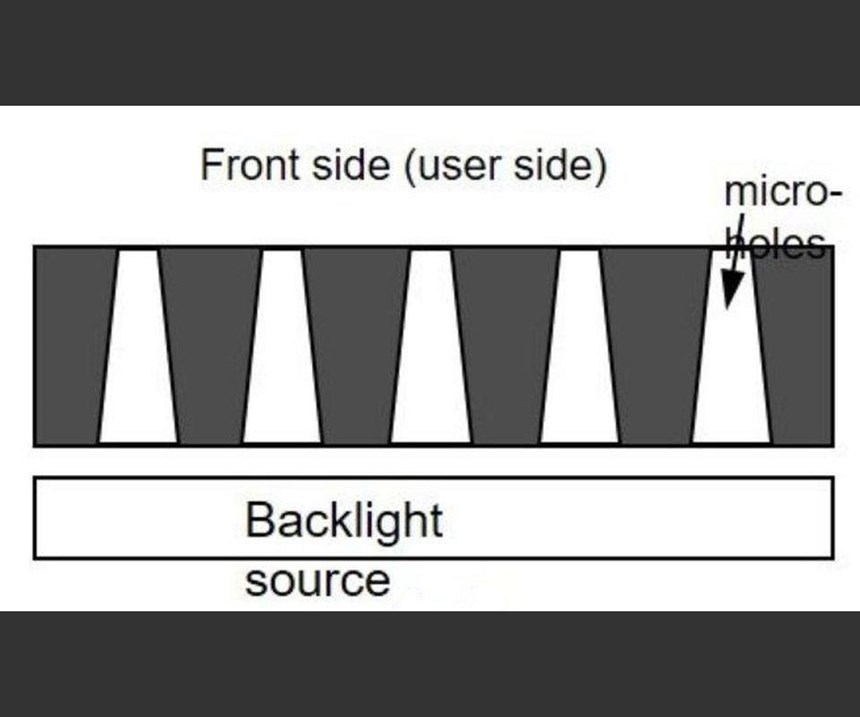

In one recent application, Potomac Laser machined conical micro-holes in control panels that would enable “invisible” backlighting. Because the limit of resolution for the adult eye is about 0.1 mm at 1 meter from the eye, the hole diameters on the user-facing side had to be smaller than 50 microns so that the hole patterns would be invisible to the viewer when the backlighting is turned off. When the light source is on, however, the display can show clear, sharp patterns using these micro-holes. The result is an unobtrusive control panel that displays needed information when relevant, but does not distract the viewer when it is not in use.

Related Content

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

-

3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

.jpg;width=70;height=70;mode=crop)