Workshops for Warriors Is a Blueprint for Success

The founder of this training program for military veterans sees it as a pattern for rethinking assumptions and attitudes about the skills gap in U.S. manufacturing.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreReaders familiar with Workshops for Warriors (WFW) may understand that its “blueprint for success” is a reference to a structured training initiative to help military veterans move into rewarding careers in CNC machining, CNC programming, welding and other skilled trades. However, Hernán Luis y Prado, the founder and CEO of WFW, says that this interpretation is incomplete. In addition to a blueprint for the success of veterans, he says that WFW is a blueprint for the success of a national program of industrial training facilities. It is also a blueprint for success applicable to owners and managers of manufacturing companies. In addition, it is a blueprint for success of the national economy.

Up-to-date equipment such as multi-axis CNC machines and instructors who provide personal attention are two reasons why WFW’s accelerated training programs are efficient and effective. Photos courtesy of Workshops for Warriors.

Luis y Prado’s thinking along these lines begins with the idea that for America to be successful, it needs a strong manufacturing base. “Manufacturing accounts for 70% of R&D spending, 30% of productivity growth and 60% of exports. Yet the manufacturing industry is still starving for qualified workers,” he says. He notes that in 2019, there were more than 500,000 unfilled manufacturing jobs and 720,000 today. This shortage of skilled workers is a crippling weakness in manufacturing that threatens to make a full recovery from Covid, offshoring and other setbacks difficult or impossible.

Welcome! You’ve unlocked premium content.

What manufacturing desperately needs is what he calls a pipeline of trained, certified and dependable workers. Luis y Prado believes that WFW is a blueprint for that pipeline, and that following this blueprint is the key to bolstering manufacturing. “If we can bridge the skills gap successfully, we can ensure the success of U.S. manufacturing and with it, the success of our country’s economy as a whole,” he says.

Preparing the Pipeline

A blueprint is a plan for building something, in this case, a conduit that streamlines skills training. Rather than transporting a natural resource to sites where it can be converted into energy or usable materials, this “pipeline” is designed to attract, refine and deliver a vigorous stream of highly employable, productive workers. WFW’s facility in San Diego is a working model of this kind of pipeline. “The blueprint is sound, and the resulting pipeline is replicable and scalable,” Luis y Prado says.

However, the WFW pipeline is distinctive in many aspects. First and foremost, it is a pipeline to move veterans and transitioning service members into careers in manufacturing technology. “Veterans represent a pool of training candidates that is already proven to be talented, competent and committed. These individuals have demonstrated their integrity, ability to make decisions, find solutions and work in teams. They have learned firsthand the importance of punctuality, dependability and resourcefulness,” he says.

Luis y Prado notes that the veteran talent pool is large and growing, with 200,000 veterans re-joining civilian life every year. More than 1 million veterans will be leaving military service in the next five years. “A high-grade, high-value resource like this is the ideal material for a training pipeline,” he says.

"WFW can help hold the line while manufacturers recalibrate their support of skills training,” Luis y Prado says. “WFW also can hold out a blueprint for the pipeline building that needs to be done."

Mix-and-Match Credentials

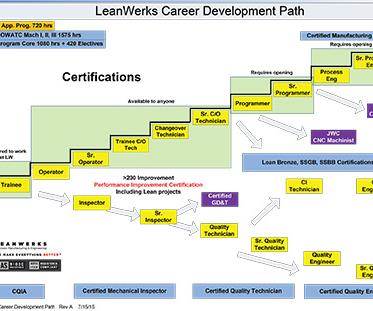

The specifications called out in the WFW blueprint are clear. The training program is concentrated, intense, immersive and accelerated — students graduate in four months. It has ample up-to-date equipment for trainees to learn on. It has enough dedicated and effective instructors to ensure that trainees get a solid foundation in both theory and practice, with personal attention and assistance tailored to individual needs. Training is comprised of core classes, advanced classes and workshops in CNC machining and welding. Classes include CAD, precision measurement, water jet operation, 3D printing and more. After completing coursework, trainees must pass tests or examinations to receive certificates from recognized industry groups such as the National Institute for Metalworking Skills (NIMS), American Welding Society, the National Coalition of Certification Centers and others.

“These credentials are stackable,” Luis y Prado explains. That is, proven competency in one skill area can be augmented with proven competency in a related or complimentary skill area. For example, CAD, CAM programming and CNC machining skills are mutually reinforcing. The WFW blueprint specifies that courses be structured to fulfill this concept.

The Challenges of Scaling the Solution

Luis y Prado emphasizes that WFW is a proven model, but replicating its success depends on adhering to the blueprint. He wants to see WFW-like training centers replicated in manufacturing hubs across the country. For one reason, many more are needed to absorb the influx of military veterans who not only stand to benefit most from the program but also are the most likely to benefit employers in need of their skills. For another reason, training centers like these can process other qualified candidates such as post-secondary graduates in civilian life who are looking for an alternative to traditional college degrees that do not suit their interests and abilities or do not make them readily employable.

Adopting the WFW blueprint presents substantial challenges, but they can be overcome, Luis y Prado says. “The manufacturing community must change its mindset,” he says. “Too many shop owners and factory managers, consciously or unconsciously, believe in the 40-20-10 rule, expecting to find job candidates with 40 years of experience, are 20 years old and will work for $10 an hour.” They blame China, the pandemic or a “kids-these-days” syndrome for the skills shortage. Others, he says, believe that automation is the answer, overlooking the fact that automation exacerbates the situation because automation almost always demands even higher levels of skill for operation and maintenance.

Instead, Luis y Prado is calling on decision-makers to invoke their own understanding of basic economic concepts such as return on investment — in other words, the importance of spending money to make money. Effective training programs such as WFW are not cheap, he says. “It costs about $25,000 for each veteran to complete the training program.” This cost is paid by program supporters such as private donors, foundations and companies such as Ford Motor Co., Collins Aerospace, Reliance Steel & Aluminum Co., Boeing, and others. Veterans going through the program do not incur out-of-pocket expenses.

Recent WFW graduate and Navy veteran Miquel Carrillo Meza exemplifies the program’s recognition that the on-going formation of a cadre of dedicated instructors is critical. Meza is one of WFW’s newest machining teaching assistants, a position offered to him because he excelled in learning machining skills and showed strong leadership ability.

At the WFW facility in San Diego, there is at least one CNC machine or a fully equipped welding booth for every two students, and approximately one instructor or associate instructor for every 10 students. Total value of equipment at the center is close to $15 million.

The return on this investment, however, is compelling. According to Luis y Prado, 95% of WFW graduates are placed in jobs right away at an average starting salary of $60,000 a year. Equally important and telling is the fact that employers hiring these graduates consistently clamor for more, he says. “We are told all the time that they will take as many of our grads as they can get.” WFW has placed graduates in all 50 states, many at high-profile manufacturing companies as well as leading contract manufacturing companies and job shops.

Luis y Prado acknowledges that funding is a barrier to reproducing the WFW prototype. “Up to now, the reason a national vocational training program has not worked is due to a lack of substantive federal support for manufacturing training, as witnessed by the infrastructure spending bill recently under consideration by Congress. Allocations for manufacturing training in the bill were quickly rejected,” says Luis y Prado, sharing his opinion that this money would have been the most likely to provide the greatest and fastest boost to a U.S. manufacturing training program.

Another obstacle to expansion is the lack of qualified instructors. Luis y Prado says that WFW has its own program for developing the cadre of professional instructors in the manufacturing specialties it offers. Most of the associate instructors are getting on-the-job training as teachers and mentors. New centers likewise will include provisions for training the trainers as an on-going adjunct to training the trainees.

Finally, Luis y Prado calls for a fundamental change in the relationship between employers and employees when it comes to recruiting and retaining manufacturing talent. “There has to be a mutual commitment and obligation between the employer and employees. You can’t demand that employees be loyal when a company can lay them off at any time. We need a social contract that says the company will pay the employee a fair wage, invest in the necessary training and that the employee agrees to stay with the company for a specific number of years,” he says.

Holding to the Mission

Luis y Prado is an optimist. When he and his wife Rachel founded WFW 12 years ago, its core mission was training — training specifically for veterans. That is still its core mission, he says, noting that WFW is successful because it has stayed true to this mission. However, he notes that training is not a core mission for most manufacturing companies. Competing in the marketplace is their core mission, as it should be, he says. Yet competitiveness cannot be advanced, let alone sustained, if a company's skilled workforce is not being renewed or enlarged.

With adequate financial support, Luis y Prado believes that WFW can increase its output of graduates significantly, from 200 a year currently to perhaps 1,000 a year, although still not enough to meet the needs of veterans leaving the service and not nearly enough to serve the needs of industry. Clearly, industry needs a national network of pipelines that can pump in the kind of trained, certified and readily deployable workers that the WFW pipeline is now producing.

"WFW can help hold the line while manufacturers recalibrate their support of skills training. WFW also can hold out a blueprint for the pipeline building that needs to be done," he says. Nevertheless, he is a firm believer in the potential for new thinking to take hold and bring about the transformation that is needed. In the meantime, veterans continue to represent what he characterizes as the cream of the crop, and should be viewed as a sizable, remarkable resource that deserves to be a priority for training programs.

Related Content

Addressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreWorkholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreRead Next

Modern Machine Shops Must Invest in Technology and Training

Investing in new technology, training and automation is a necessity for keeping up with the changing nature of manufacturing, according to Tony Staub, founder of Staub Precision Machine Inc.

Read MoreShop's Own Training Program Paves a Pathway to Employee Success

This shop developed a Web- and video-based training program tailored to its own specific practices that enables new hires to progress in stages from trainee to senior process engineer after demonstrating a clear understanding of each new skill they’ve acquired.

Read More

.png;maxWidth=150)