Workholding That’s on Point

A pin-based workholding system quickly accommodates workpieces of any shape.

Share

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Did you or one of your kids ever play with one of those pin impression boards? The idea was that you could press any object—a smaller toy or a hand, for instance—gently into the pins on the back of the board and see a crude relief image on the other side.

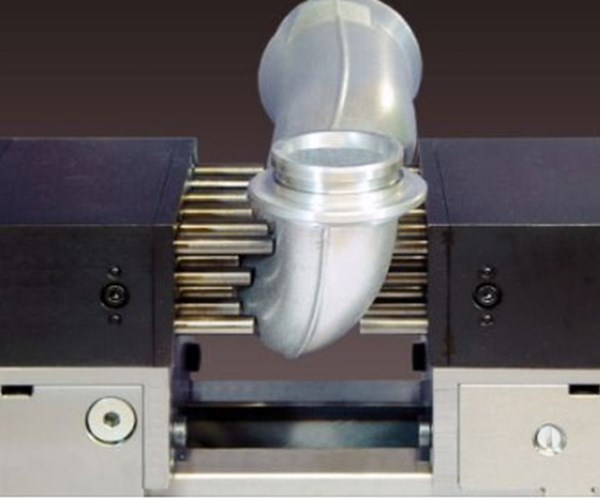

A clamping element from Euro-Tech called “The Jaw” (pictured above) works in a very similar fashion. The product has a number of hydraulic pins on each side that quickly conform to the shape of any part placed between them. Internal clamping sleeves lock the pins in place, and the company says that the form fit reduces required clamping force. The adaptable system can be used as jaws for vises, as supports, and in combination with robot grippers and other custom solutions.

Related Content

-

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)