With Retention Knobs, Shop Sets Sight on Aerospace Machining

Mitch and Brian Olson didn’t know much about CNC machining when they started their machine shop, but they learned that if they wanted to pursue high-accuracy aerospace work, they would need to overcome a flaw inherent in V-flange tooling.

Share

In 2014, brothers Mitch and Brian Olson started Olson Custom Designs (OCD), based in Pittsboro, Indiana. Although they had extensive backgrounds in both motorsports racing and fabrication, neither had much experience with CNC machines prior to starting the company. So, because CNC machining is the backbone of OCD’s custom machining and fabrication operation, investments in the right machines were of vital importance to the family-owned job shop, which services myriad industrial markets including aerospace, medical, motorsports and agricultural.

The Olsons purchased two vertical machining centers from Haas Automation: a VF-4 Profile and a VF-2YT Profile. The VF-4 provides a machining area of 50 by 20 by 25 inches, with a vector drive of either 30 hp or 22.4 kW, and a spindle speed of 15,000 rpm. It is equipped with an inline direct drive and a 40-station carousel toolchanger. The VF-2YT provides a machining area of 30 by 20 by 20 inches, with an 8,100-rpm spindle, internal coolant system, direct drive and a 20-station toolchanger.

“We needed to invest in machines that we could push to the limit on every job,” Mitch Olson says. “Using only the most modern methods would allow us to compete and achieve the highest-quality parts without sacrificing time or energy.” He says that the shop fosters an attitude in which the words “standard” and “good enough” do not cut it. The right machines help to achieve that.

With these major investments secured, the Olsons sought out tooling solutions to push their three- and five-axis milling machines to the limit. In particular, they wanted to address any problems up front with the interface of toolholder and spindle on the new high-rpm/high-torque equipment to make certain it would operate consistently and efficiently and be protected from long-term production issues.

“At the end of the day, we focus on a lot of custom, complex geometries and machining tight-tolerance parts out of stainless steel, aluminum and other hard exotic alloys like titanium,” Brian Olson says. He adds that this meant they needed their machines to run quickly and without interruption while maintaining accuracy.

Fitting the Toolholder to the Spindle

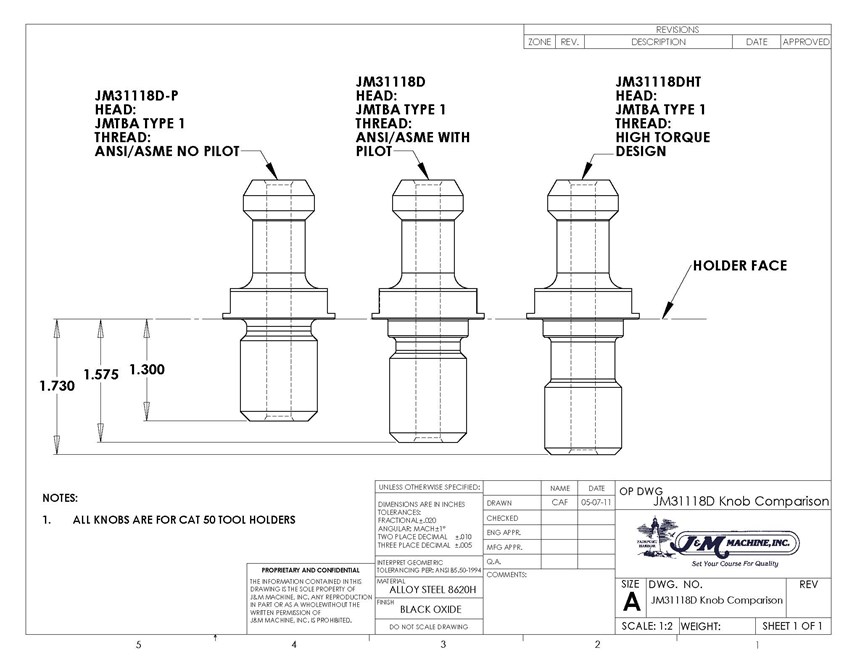

During initial product demonstrations at the Haas Tech Center, the subject of retention knobs was discussed. The brothers were given a demonstration comparing the high-torque retention knobs offered by JM Performance Products (JMPP) of Fairport Harbor, Ohio, to standard, off-the-shelf retention knobs, which presented potential risk of shearing off or breaking because of high cutting forces.

“The Haas demo is similar to the one we give at shows like the International Manufacturing Technology Show (IMTS), where we test both types of knobs with a gage,” says Dick Brimer, technical sales and support manager with JMPP. “The demonstration confirms that most standard retention knobs create expansion at the small end of the toolholder, causing bulges that result in the toolholder not going into the spindle all the way.”

Since tight tolerances are essential in high-speed machining, fit the spindle preciselydoes notif the toolholder , decreased productivity and reduced tool life are inevitable. Mr. Brimer explains that JMPP’s retention knobs feature a relief between the top thread and the flange that enables the thread to fit deeper into the holder, making it more stable and keeping toolholder expansion to a minimum, if it expands at all. By increasing contact with upward of 70 percent more of the spindle surface, a wide range of CNC milling issues are overcome, according to JMPP, including vibration and chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear and tear, runout and shallow depths of cut.

Mitch Olson says that the demonstration had a big impact on him and his brother. “We’ve got a lot of money invested in the tooling, and without the right retention knob, it could affect everything on the whole mill. The demonstration showed us how JMPP’s knobs provided better overall finishes, required less hours and shorter runs for us as a job shop. That’s why we started with their knobs.”

Pursuing Aerospace Quality Certification

OCD currently has seven machines in its 5,000-square-foot shop, including three milling machines and four lathes. As production continues to expand, they have been planning a move into a 24,000-square-foot facility. Additional machines that have already been purchased for this expansion include a Mazak VC-500 AM hybrid multitasking machine.

The VC-500 AM combines full five-axis capability and additive technology, which the shop hopes will reduce time to market and cut R&D costs. Like all of OCD’s 40-taper machining centers, the VC-500 AM machining center will be using JMPP’s high-torque retention knobs.

The company also is moving heavily into the aerospace market and expects to complete its AS9100 certification soon. The quality-management standard is important for aerospace manufacturers and suppliers, which require compliance to AS9100 as a condition of doing business. The pursuit of more aerospace work is one reason why the shop relies on the accuracy promoted by the retention knobs.

“We will often machine exotic alloys and harder metals like titanium and stainless steel. We won’t skimp out on tooling or workholding,” Mitch Olson says, adding that JMPP’s knobs are critical to the process, helping to ensure quality feeds, speeds and finishes.

Related Content

DN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreFryer Milling Machine Provides Fast Setup, Simple Programming

The MB-R toolroom bed mill is reportedly capable of single- or multi-part production with a 0.0002" accuracy.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More