Wireless Workholding Meets the Grease Arbor and More

In addition to live, small-batch automation, SMW Autoblok's varied display highlights new technology as well as new takes on traditional techniques.

Share

Some showgoers might have never heard of a “grease arbor,” a term for a traditional inner-diameter clamping device. They might be more familiar with the standard chuck, but have likely never seen chucks with jaws that move individually to grip irregular or fragile geometries, or that do so without any hydraulic or wired connection.

Both clamping technologies are on display at SMW Autoblok’s booth, where a slew of new brands and products reveal a push to cover every facet of the workholding marketplace.

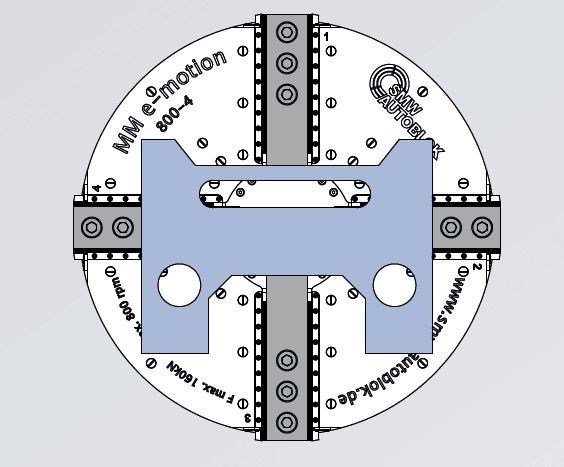

Different wall thicknesses, special geometrical forms and both ID and OD clamping are all ideal for chucks with individual jaw control. This level of control is possible thanks to inductive couplers that enable wireless transmission of both power and data. Photo Credit: SMW Autoblok Corporation

In keeping with its goal of integrating electronic and mechanical systems, SMW Electronics is showcasing its E-motion line of chucks with individually moving jaws. Highlights for manual workholding include displays from SMW acquisitions Tobler and Telbrooke. Tobler is a Swiss company that has been manufacturing expanding mandrels (“grease arbors”), OD clamping collets and other workholding since the 1840s, while Telbrooke is a British specialist in custom aerospace workholding and manual steady rests.

The display also highlights what Larry Robbins, CEO of SMW America, calls “older tech with new flare.” For example, magnetic workholding is not new, but products from new SMW acquisition Technomagnete might be applied in a new way via capabilities like daisy-chaining, in which multiple magnetic chucks share a single control unit. Also, Robbins says, Tobler’s expanding mandrels can be advantageous in applications that might be more difficult with traditional chucks. He cites the example of leveraging a “pull-back” style mandrel to simultaneously center and locate features on a turned part.

Regardless, there is nothing traditional about the focal point of the display, a robot changing its own grippers to swap vises, chucks, mandrels and other varied workholding in and out of a mock machine tool spindle. The demonstration is meant to spark ideas for applications on virtually any form of machine tool, even without high production quantities.

From the racking to the chucks themselves, the demo is also meant to be brand-agnostic. “We’re showing that we have the ability to integrate anybody’s technology under our own umbrella and do integration for automation, which we’ve never done in the past,” Robbins says.

Related Content

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

.jpg;maxWidth=300;quality=90)