Why Shops Are Looking More to Swiss-Types

These days, more traditional job shops are installing—or at least eyeing—Swiss-types. Here are some reasons why.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

When CNC Swiss-type lathes were introduced, screw machine shops were the first to integrate them. Those machining businesses traditionally used cam-actuated screw machines to produce parts because, once set up for a specific job, that reliable equipment offered the speed and productivity needed for effective high-volume work. CNC Swiss-types complemented the mechanical screw machines by providing versatility to produce relatively smaller batches of precision turned parts.

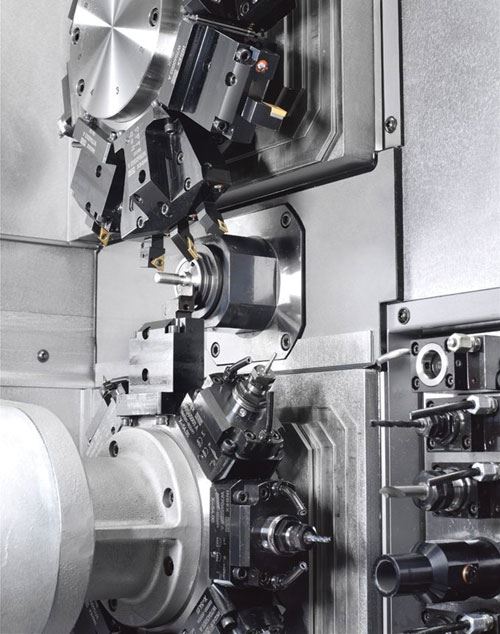

These days, more traditional job shops are installing—or at least eyeing—Swiss-types. That’s largely because Swiss-types can rapidly perform both turning and milling operations, enabling shops to machine intricate parts complete rather than running them across multiple machines. Recognizing this, manufacturers of Swiss-types have integrated design elements into their sliding-headstock machines to boost their effectiveness in environments where the work is diverse and the batches are small.

Traub is one such Swiss-type machine builder. (Traub is a subsidiary of the Index Group.) The manufacturer, which recently introduced the 20 mm-barstock capacity TNL18 and lower-priced TNL18P Swiss-type lathes, cites a handful of ways this machine platform has evolved to become an attractive alternative for conventional job shops.

“Tiered” Machine Offerings

Many Swiss-type builders offer varying levels of sophistication and price points within a given machine line. By limiting the number of machine features to only those that are essential, the builders are able to provide effective Swiss-type performance at a lower cost to shops with no Swiss-type experience. This is the case with Traub’s TNL18P. The TNL18P is a 10,000-rpm, five-axis machine, whereas the 12,000-rpm TNL18 is available in seven- or nine-axis versions. The TNL18P includes a reliable TX8i-p Mitsubishi control with a 10.4-inch LCD display and integral keyboard, versus the TNL18’s 64-bit Tx8i-s control with industrial keyboard. Both machine versions, however, offer simultaneous machining with up to 3 tools, a vertical bed design to facilitate chip flow, and chip-to-chip tool change time of less than 0.3 seconds.

Convertibility

The guide bushing is a Swiss-type’s signature machine component. It provides barstock support at the point of the cut to enable effective turning operations of parts such as bone screws with high length-to-diameter ratios (typically greater than 3:1). However, costly, ground barstock is typically required when using a guide bushing to eliminate the chance that the barstock will stick as it’s pushed through the bushing. Machining with a guide bushing also creates longer barstock remnants, limits the distance the barstock can be retracted back into the guide bushing during machining, and introduces another step in the setup process for new jobs.

In fact, a lot of work performed on Swiss-types doesn’t necessarily require the use of the guide bushing. This is why some Swiss-types can operate with or without their guide bushing. By removing the guide bushing assembly (which, according to Traub, takes just 15 minutes), Swiss-types can perform roughing and finishing operations like conventional lathes. Running in “chucker mode” can help operators who are new to Swiss-types become comfortable with the new type of machine faster.

Quick Change-Overs

Job shops make money by minimizing downtime due to job change-overs. Using tooling that enables setup personnel to change tooling elements while leaving the tool body in the machine goes a long way toward reducing the time to change-over Swiss-types for a new job. Traub says this is why it offers a healthy selection of quick-change tooling with its machines.

Of course any shop must be able to justify the addition of a new machining technology. Traub suggests performing a thorough return-on-investment (ROI) study to determine how integrating an advanced machine will impact a company’s cash flow and machining profitability based upon the expected revenues and expenses. In some cases, a faster, albeit more costly machine will deliver a lower total production cost per workpiece than less-expensive equipment.

Related Content

How to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreMultitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)