Which Kind of "More So" Are You?

The coronavirus pandemic has brought many people, businesses and industries to a standstill. How are you reacting?

Share

Sorry, but this is not a normal “CNC Tech Talk” column.

I have never felt such a loss for words in over 30 years of contributing to Modern Machine Shop. Ideas have always come easily to me, commonly stemming from some CNC problem I encounter. A question asked and answered often translates into an easy-to-write column.

But it has been different lately. Like so many others, I have been hunkered down and minimizing trips outside of home. The grocery store and post office have been my only destinations for the last few months. And there is a looming concern for family members, especially the weaker and older ones.

I cannot bring myself to write about some slick CNC technique or custom macro or parameter setting. Instead, I am sharing my feelings about what we have all been experiencing (and will probably continue to experience well into the foreseeable future).

If you are naturally a person/entity who sincerely cares for others, then you have probably found ways to be more so during this pandemic, printing face shields, machining ventilator parts, donating to charities and trying to make things a little better for others.

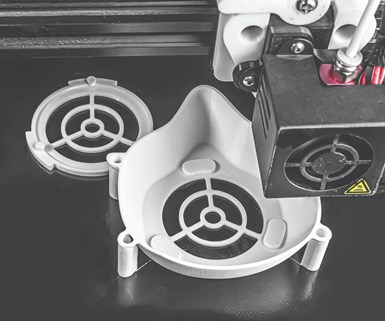

My work involves answering emails, maintaining e-learning services and filling orders. This takes a fraction of the time it did just a couple of months ago. With the extra time, I have put my two hobby-grade 3D printers to work making face shield components. I ship them to requesters from operationdynamo.org — a platform for connecting volunteers with 3D printers to requests for parts from hospitals during the pandemic. Fortunately, we have had a mild spring, and I fill the rest of the day helping my wife in her wildflower garden.

The first disruption to affect those of us with children were the school closings. All have closed their doors for face-to-face classes, but most remain open for remote learning. Many have scrambled to create or enhance their online presence. Educators, like my daughter and son-in-law, have had to modify their teaching methods, often having to create new content from scratch. Students, with their parents’ help, have had to adjust their expectations and efforts to match. School celebrations have been curtailed. My grandson’s graduation from the U.S. Naval Academy was canceled. For two other grandkids, high school and middle school graduations have been indefinitely postponed. No proms, no class picnics, no trips.

These things are trivial compared to the issues many others are facing. Medical workers are being asked to risk their lives with inadequate protections. Similar challenges face delivery people and grocery store workers. Tens of millions people have applied for unemployment compensation.

Though we in manufacturing appear to have been a bit more fortunate, I am sure many would disagree. Lots of manufacturing facilities have remained open, though even the safeguards put in place to curtail spread of the coronavirus aren’t foolproof.

In the midst of this turmoil, here is something I found to be inspiring and insightful. Every day, my wife and I read Amy Dickinson’s syndicated column, “Ask Amy.” In one column from a few weeks ago, she quoted someone’s interpretation of how people are responding to the pandemic:

“People are becoming ‘more so’. If they were kind and thoughtful and inclined to be loving before, now they are more so. They are finding ways to help and finding those who need help, whether it is through sharing time, money or kindness. Those of us who were angry and scared and suspicious before, sadly, they too are now more so.”

While the writer was referring to people, this can easily be expanded to include companies and organizations. If you are naturally a person/entity who sincerely cares for others, then you have probably found ways to be more so during this pandemic. These people/companies are sewing face masks, printing face shields, machining ventilator parts, donating to charities, and in general doing their bit to make things a little better for others. On the other hand, if you or or your shop’s management are normally angry, scared or suspicious, you’re probably not helping the cause.

When history judges us — and it surely will — which kind of “more so” will you have been?

Related Content

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

Shop Starts Work on Custom Drill for Ventilators Before Purchase Order Came

When this Indiana toolmaker saw an order for cutting tools to make ventilators for coronavirus patients, his workers started grinding before the customer officially hired them.

Read MoreAerospace Supplier Shifts to Tight-Tolerance Ventilator Parts: "We Weren't in This Business Two Weeks Ago"

Skilled Manufacturing Inc. is running seven days a week to produce ventilator parts that will help healthcare workers battle the coronavirus.

Read MoreDie Maker Describes Five-Day Build for Tool Urgently Needed for Coronavirus Ventilator Production

Running 11 five-axis machines simultaneously, a die maker reduced a five week lead time to just five days. Here’s how.

Read More

.jpg;width=70;height=70;mode=crop)