Share

Takumi USA

Featured Content

View More

This content originally appeared on our sister brand, Additive Manufacturing. Check out more additive content at additivemanufacturing.media.

“If you want to buy car insurance today, you can go to a number of websites and get half a dozen quotes in a few minutes,” says Stephan Abt of Plus Manufacturing. But no such equivalent exists for the manufacturer trying to choose between half a dozen or more solutions. “Where does an engineer or designer go to compare different manufacturing processes and materials when developing a part?” Abt asks.

Of course, comparing manufacturing methods is slightly more complicated than comparing insurance coverage from different providers. When the potential options might include everything from aluminum sheet metal bending to steel CNC machining to, yes, additive manufacturing, maybe in exotic materials, it’s much more difficult to reach a true apples-to-apples comparison and there is more inertia to fight with any given change. But this Erlanger, Kentucky, company has developed a tool that distills information about a given part to help engineers and companies make better-informed decisions about how to manufacture it.

The free decision-making tool is called COSMO, which stands for Cost Over Specific Modulus. Available for free download and use through a Creative Commons license on Plus Manufacturing’s website, COSMO is a spreadsheet with automated formulas that enables users to compare the cost, lead time and other variables for different materials and manufacturing methods, including a metal deposition AM process Plus Manufacturing has developed. (For now, the tool primarily considers metal manufacturing processes, but the company has reached out to other firms including plastic 3D printing companies and will continue to expand its scope through collaborations.)

To use the tool, users plug in details about the part they wish to make and select the processes under consideration. Using the specific modulus (stiffness-to-weight ratio) as a stand-in for the part’s end-use performance requirements, COSMO provides the user with information about the typical costs associated with manufacturing it, including material, labor, finishing, corrosion protection, capital equipment and even floor space. Based on the part, process and materials selected, the tool outputs tables of information that make it easy to compare the different options and select the best one for the intended use case.

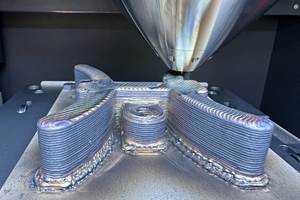

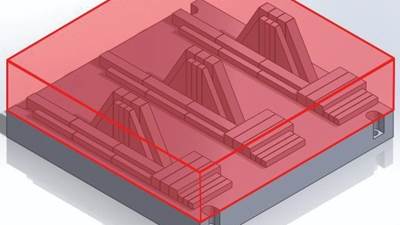

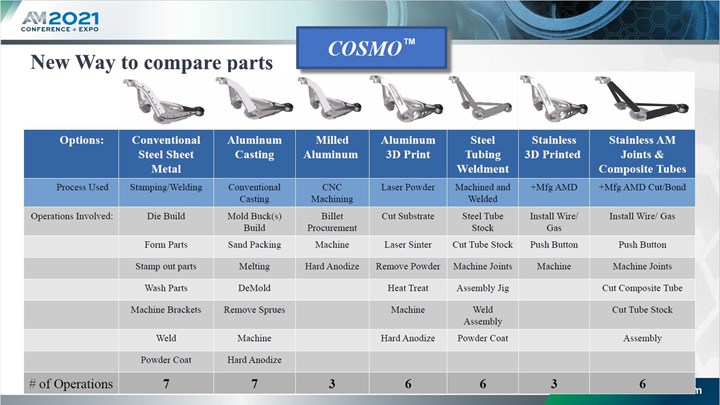

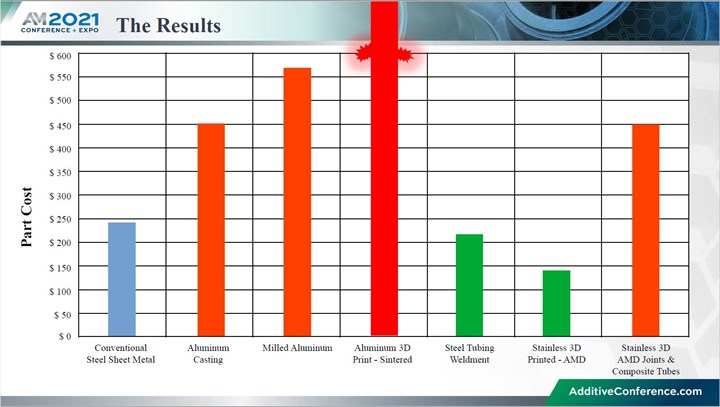

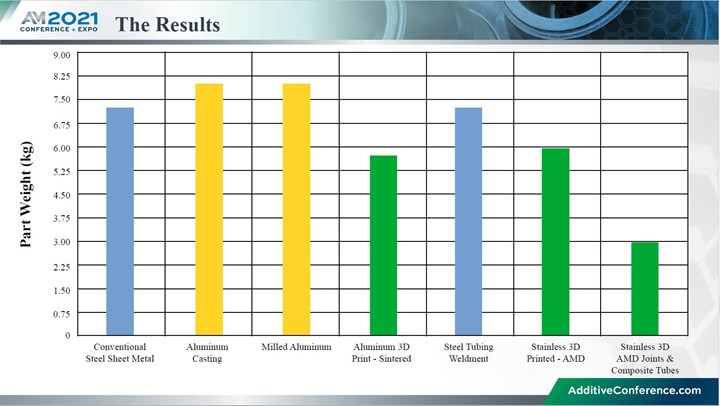

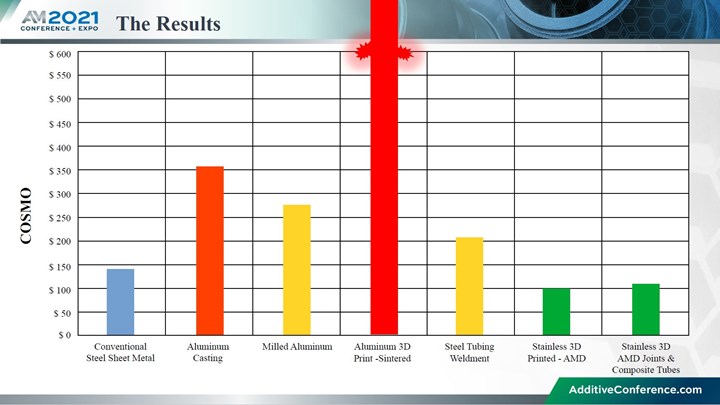

For instance, for the electric vehicle A-arm pictured here, the automotive manufacturer might input the approximate part dimensions and manufacturing options being considered. COSMO could then deliver the results shown below, which compare steel sheet metal, aluminum casting, aluminum milling, aluminum powder bed fusion, steel tubing weldment, full production via Plus Manufacturing’s own Advanced Material Deposition (AMD) 3D printing method in stainless steel, and a combination of AMD stainless steel joints and composite tubes.

Number of operations required to make the A-arm using each process. All slides are taken from a presentation delivered by Stephan Abt, Plus Manufacturing engineer, and Tom Kruer, chief innovation officer, at the 2021 Additive Manufacturing Conference. Image Credit: Plus Manufacturing

As shown above, milled aluminum and AMD stainless steel result in the fewest number of operations; conventional sheet metal and aluminum casting (which both require long-lead-time tooling) have the most.

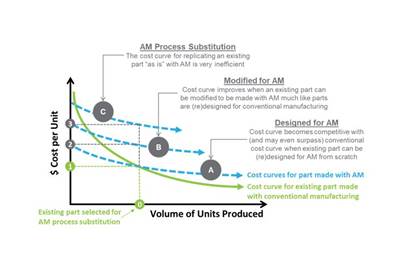

The cost-per-part comparison of the processes reveals that aluminum laser sintering AM is the costliest process. (Note that for processes that rely on up-front tooling such as stamping and casting, the cost of the tool is factored into the cost per part, divided across the expected batch size. These processes can achieve economies of scale at higher volumes, whereas the cost per part for additive manufacturing tends to remain stable.)

The three additive processes considered offer the lightest weight components; conventional aluminum casting and milling are the heaviest options.

The cost and weight comparisons are valuable on their own, but engineers and designers are often striving for the strongest and lightest part at the lowest cost. According to Abt, the COSMO parameter (shown above) provides a single, objective number to allow comparison between materials and processes. In the current A-arm example, the calculated COSMO parameter illustrates that the AMD process produces a strong yet lightweight part out of stainless steel, while the cost comparison shows it is competitive with steel sheet metal or an aluminum casting.

Plus Manufacturing acknowledges that specific modulus might not always be top concern, so part weight and cost comparison results are provided for cases where these factors, regardless of performance, might be highest priority. And although Plus Manufacturing is an AM technology supplier, the final conclusions derived through COSMO are not any more likely to turn up additive manufacturing as a solution — instead the goal is to get to the most efficient production method for the part. COSMO is meant to help business leaders and engineers question and test their assumptions, with confidence in the result.

The advantage of a tool like this, Abt says, is that it can actually help those involved in manufacturing change their thinking. A decision-making process based on data like this helps shift an engineer from defaulting to their typical production process. Instead of saying, “Let’s make this new part out of sheet metal — I know how to do that,” that engineer might instead decide to pursue composite or additive manufacturing, because the advantages over sheet metal can now be quantified. COSMO has the potential to get engineers out of their own heads and help them consider other production methods, including additive, with confidence.

“It allows engineers to go down a path knowing that it leads to a reasonable result,” Abt says.

Related Content

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreRead Next

Why Does My 3D-Printed Part Cost So Much?

The machine, the facility and the material are just three costs behind the price tag.

Read MoreSpeed Is Relative in AM: A Data-Driven Comparison of Multi-Laser Powder Bed Fusion and Binder Jet Processing

There is a difference between the effective print speed and the actual cost to produce the component with AM. John Barnes compares binder jet processing with powder bed fusion for metal parts.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)