What Do Online Marketplaces Really Deliver To Job Shops?

Online custom manufacturing marketplaces really can deliver a stream of RFQs to metalworking job shops. The question is, how do job shops actually convert the opportunity into real business? (2002 Guide To Metalworking On The Internet)

Share

Autodesk, Inc.

Featured Content

View More

In the interest of full disclosure let me begin by saying that we, Gardner Publications, have a business interest in an online marketplace for machining services. The "Bid For Work" area that you see in MMS Online is a partnership we have with MFG.com (Smyrna, Georgia), an independent company that extends a single online marketplace to a broad audience through a variety of industry "portals" such as ours. But my purpose here is not to convince you how great Bid For Work or any online marketplace may be. Rather, it is to look at the opportunities that are provided by these marketplaces in general, and to offer some insights into how job shops might better compete in this very new market environment.

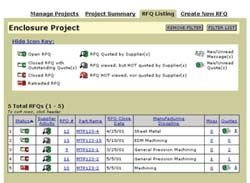

Like its off-line counterpart, the online marketplace provides a means for buyers of machining services and job shops to find one another and do business. In the online version, however, buyers need not search out potential suppliers through directories, word-of-mouth recommendations or other manual means. Likewise, job shops are spared the tedious process of identifying new potential customers and then making the sales contacts that they hope will lead to a quoting opportunity. Instead, buyers post their requests for quotes (RFQs) on a password-protected Web site, and then job shops that are part of the marketplace are invited to download the RFQ information and bid on the work.

The people who operate online marketplaces generate their revenues in several ways. Some charge a transaction fee for jobs awarded through the marketplace, which is typically some percentage of the value of the job. Others charge flat or scaled subscription fees, typically paid by the sellers. Some have combinations of both.

As for how they conduct business, some marketplaces rely on "reverse auctions." In these cases, there is an open bidding process for a given job or contract over a relatively small span of time. Everyone can see what everyone else is bidding, and all watch as the price is driven down until the auction is closed. This model is obviously designed to serve the interests of the buyer, with price being the dominant—if not only— factor in deciding who gets the work.

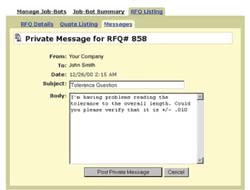

Other models rely on a confidential bid process that more closely resembles how conventional RFQs and quotes are handled. This model seeks to provide better balance in serving both the buyers' and the sellers' interests. If done properly, it also supports other important aspects of an off-line RFQ process, such as the job shop's ability to trade engineering information with the customer, suggest process alternatives, and to accentuate other aspects of a shop's true capabilities.

Transparency Changes The Game

Regardless of which revenue or business model you are talking about, the online marketplace brings about two important changes in the marketing outlook for a job shop. First, it gives the shop access to a much broader range of potential customers than it could ever hope to meet on its own, dispersed over a much larger geographic area. Second, it gives the buyer a much better view of benchmark price levels for the kinds of parts that company buys. Now shops are literally competing with other shops all over the country, which shifts the historical competitive advantage of geographic proximity (to a customer) to an advantage for shops with the specific capabilities that best meet that specific customer's needs.

The marketing gurus refer to this idea as "market transparency." Market participants on both sides of the transaction can now more clearly see their options rather than being constrained by local or regional market conditions, or simply by the fact that their only good existing sources of information are the companies with whom they already do business. That's admittedly a threatening proposition for some job shops, as it is no longer possible to rely on the ignorance of customers to maintain artificially high price levels for any given grade of work. But it is also an opportunity for shops to dramatically extend their customer reach for the kinds of work at which they excel.

Moreover, a balanced (in terms of serving both buyer and seller interests) online marketplace provides the opportunity for shops to meet new potential customers at the precise moment that they are in need of the job shop's services. It is a critical moment because the opportunity is not just to land an order, but also to establish a relationship with a new customer that could mean much more business down the road. That's not just speculation. According to Mitch Free, president of MFG.com, many of the shops that find new customers through the MFG.com marketplace do indeed go on to receive additional work from those customers, both online and off-line.

How Do You Compete?

For a balanced (non-auction) online marketplace, the important thing to keep in mind is that online buyers award jobs for essentially the same reasons that off-line buyers do. Do they want to know that they are getting a good price? Absolutely. But is price is the only issue? Not at all. Indeed, according to Mr. Free, 92 percent of the RFQs awarded through MFG.com do not go to the low bidder. Just as important, at least in most cases, buyers want to be assured that they are working with a competent and reputable vendor. Ultimately, it is a variety of factors that influence the final selection, as well it should be.

What kinds of job shops excel in this environment? According to Mr. Free, "The most successful job shops refine their sales skills, know their value proposition and can articulate it well, on and off-line. They focus on the type of work they do best and leverage specific areas of expertise or specialized equipment."

That's saying a lot; so let's break it down a bit. Step one in competing in an online marketplace is understanding the type of work in which your shop is truly competitive. There is no point in quoting a lot of jobs you have no chance to land. The unvarnished truth is that RFQs for very simple jobs are heavily quoted and, particularly in the current economic environment, quoted at very low prices. As the work grows more complex, however, the prices go higher and the number of quotes per job drops. Pick a sweet spot somewhere on that continuum that aligns well with the combination of your equipment and expertise and that has a reasonable chance of meeting your margin requirements.

Step two is finding a way to differentiate yourself from the pack once you've decided to quote a job. Realize that the customer is taking considerable risk in giving an order to a new supplier, sight unseen. Anything you can do to put the buyer at ease with your professionalism will be rewarded with stronger consideration for your proposition.

First of all, do the fundamentals right. Make sure your quote is accurate, clear and free of misspellings. Also, if the marketplace mechanism supports collaborative interchanges, seek out opportunities to further engage the buyer with helpful questions about the job requirements, or offer suggestions that may improve the manufacturability of the part. Admittedly, a lot of seasoned job shop managers will argue that, even in this day and age, relatively few buyers respond well to job shop suggestions of this nature. Even so, the effort will say something very positive about your base of knowledge. Moreover, everyone these days is looking for ways to reduce cost. If you can figure out a way to help save your customer money through a process or design enhancement, chances are very high of being rewarded for the contribution.

Equally important, make it easy for the buyer to further validate your shop's presence in the market. That can be as simple as offering references from other customers who are familiar with your work.

Better yet, if you are going to get engaged in online markets, consider developing a good Web site for your business. Professional, clean Web sites can give shops an edge over their competition as buyers perform their due diligence. Providing a link to your site in the quote will help buyers learn more about your shop, its equipment, its expertise and its experience. That will be important and appreciated as the buyer takes a measure of the companies behind the quotes on the computer screen. Another advantage of a Web site is that it can be a great equalizer. Even very small shops can appear professional and competent with an informative online presentation.

Finally, it is important to understand that online marketplaces were designed to augment sales and marketing initiatives, not to replace them. Think of it like this: The online marketplace is a new channel that neatly provides access to potential new customers who want to buy the very same services that you want to sell. But all the marketplace can do is deliver the chance. You're the one who has to close the deal.

Related Content

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)