Weingärtner Mill-Turn Widens Plasticizing Screw Production Range

Weingärtner’s custom Pick Up mill-turn center for injection mold machine manufacturer Arburg has widened the range of plasticizing screws Arburg can produce.

Share

Despite traditionally using whirling machines for producing plasticizing screws, Arburg has shifted to milling technology.

Due to the varied properties of plastics, material preparation and processing play a key role in the injection molding process. In turn, this makes the plasticizing unit on the injection molding machine a central component, posing challenges for manufacturers’ design, development and production teams. With this in mind, Arburg GmbH + Co KG decided to replace its existing whirling technology with a more flexible method of screw production. It invested in a custom mill-turn center from Weingärtner Maschinenbau GmbH (Kirchham, Austria).

Arburg is a manufacturer of plastics processing machines. Over 70% of its sales are exports, and about 60% of production takes place in house. Moreover, it develops both hardware and software in house and only produces at its Lossburg, Germany, facility. Despite relatively high production quantities, Arburg does not maintain a stock of machines and often produces in single lot sizes to accommodate specific customer requirements. According to the company, its customers typically invest in a plastics processing machine only when they have a concrete order in hand, so a tight turnaround is essential.

All the measures that render a material highly abrasive and highly resistant to corrosion make it more difficult to machine.

“Our machines are generally used to process highly technical plastics that are enhanced with various filler materials such as glass fibers,” says Stefan Holzer, Arburg graduate engineer and team leader for production planning and process optimization. “This constantly results in new materials, all of which place enormous demands on the plasticizing screws. At the same time, the geometries are becoming more and more complex and the materials increasingly difficult to machine. The extruder blanks are frequently hard-faced, coated or contain stellite alloys. In other words, all the measures that render a material highly abrasive and highly resistant to corrosion make it more difficult to machine.”

With increased demands placed on plasticizing screw production, Arburg managers concluded that the future of its screw machining technology lay in milling — not least, because they knew it had the power to increase production flexibility, and because the wider selection of milling machine manufacturers suggested a greater variety and speed of innovation, Holzer says.

A CAD for the Occasion

Along with the mechanical engineering of Weingärtner’s machines, Holzer says “the thing that particularly won us over was the integrated programming tool. This enables us to accommodate the many different plasticizing screw contours with just a few tools, keeping the amount of effort associated with tools manageable for us.”

Weingärtner’s WeinCAD software package is specifically developed for extruder and injection molding screw production. It is designed to handle everything from process development and geometrical design to automatic generation of the program for the control system. It can also provide a 3D simulation of all machining processes.

Bigger and Better Applications

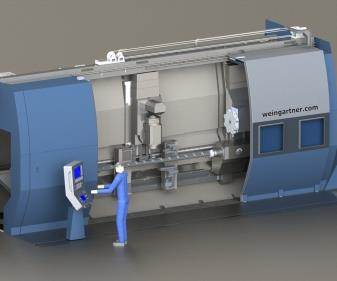

Weingärtner’s custom Pick Up for Arburg incorporates well-received features from its classic Pick Up series, such as a clamping concept involving prismatic jaw steady rests.

Arburg paired WeinCAD with Weingärtner’s mill-turn center from its Pick Up 400 series, which Weingärtner says it specially designed to enable the fully automatic production of screws for injection molding machines. The Pick Up 400 mill-turn center machines screws measuring up to 160 mm in diameter, 6,000 mm in length (although Arburg’s model has a maximum length of 4,700 mm) and 1,200 kg in weight. Its standard 45 kW milling unit has a torque of 275 Nm and runs at a speed of 1,560 rpm — while the specifications list a speed of 14,000 rpm, Weingärtner says this value applies to a 100% duty cycle, also known as continuous S1 operation.

Weingärtner’s Pick Up 400 also includes a clamping concept involving prismatic jaw steady rests, two independent machining cells for simultaneous machining of two workpieces and full upstream automation that enables the system to run with what the company says is almost no assistance from humans.

As far as we are concerned, this mill-turn center from Weingärtner goes a long way towards making us future-proof.

Holzer points to the Pick Up 400’s length as a future-proofing advantage. “Arburg started out in the field of smaller injection molding machines but our customers were constantly urging us to supply larger systems as well,” he says. “However, this also means that our production facilities have to keep pace and grow at the same rate. The Weingärtner machine allows us to machine a much wider range of screw dimensions. As far as we are concerned, this mill-turn center from Weingärtner goes a long way toward making us future-proof. It means that we can forge ahead with larger diameters and lengths while at the same time adapting our production processes in line with the advanced possibilities offered by modern machines. We are still a long way off from exhausting the full mechanical capabilities of the Pick Up and so have more than enough capacity to spare.”

Custom Optimizations

Together with the automation section and additional components, the Weingärtner machining center measures approximately 25 m in length. To improve accessibility, Arburg sunk the machine into the factory floor to a depth of 60 cm.

Arburg and Weingärtner designed Arburg’s custom Pick Up 400 on the basis of a detailed requirements specification developed over the course of numerous joint meetings between the two companies’ project teams.

At time of publication, Arburg is still actively creating milling programs for its hundreds of different plasticizing screws. While this means it has yet to see the machine’s full capabilities, Holzer and the rest of the Arburg team are confident that the machine provides Arburg with a competitive edge — Arburg has even ordered a Weingärtner MPMG 400 and CNC abrasive belt polishing machine to compliment its Pick Up 400.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Turn-Mill Enables Screw Machining Complete

Weingärtner’s Pick Up 400 turning and milling center is designed for the manufacture of complex screw geometries such as extrusion and feed screws.

Read MoreTurn-Mills: Being About the B-Axis

With the addition of powerful B-axis milling spindles and automatic toolchangers, turn-mills combine the best of milling and turning worlds.

Read MoreMultitasking Machining Equipment: Now the New Normal

Equipment that can turn, mill and more is quickly becoming the standard in metalworking technology. These machines can produce increasingly complex parts in a single setup yet are easier operate than ever before.

Read More